CNC Machines for Aluminum & Brass Machining

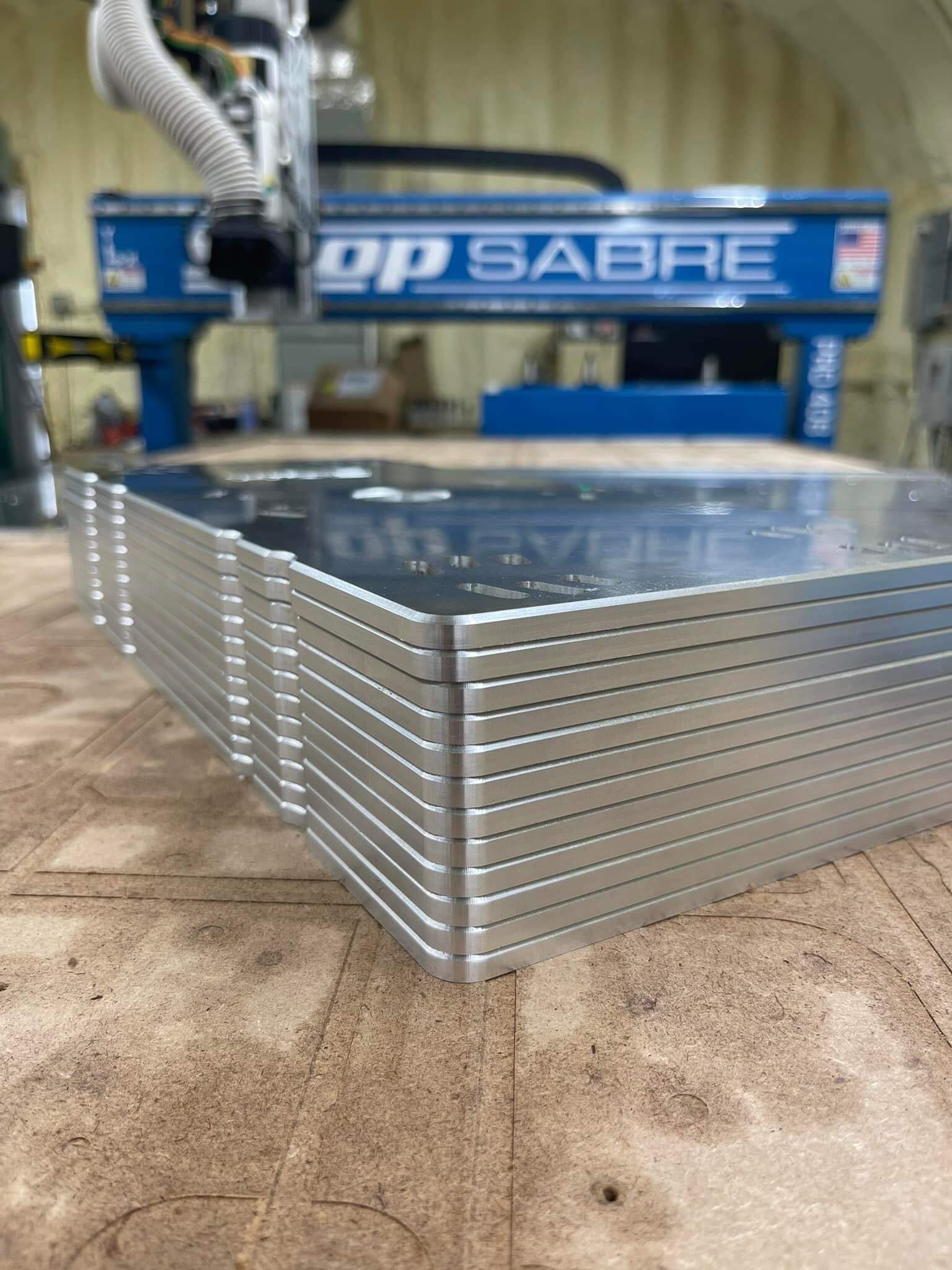

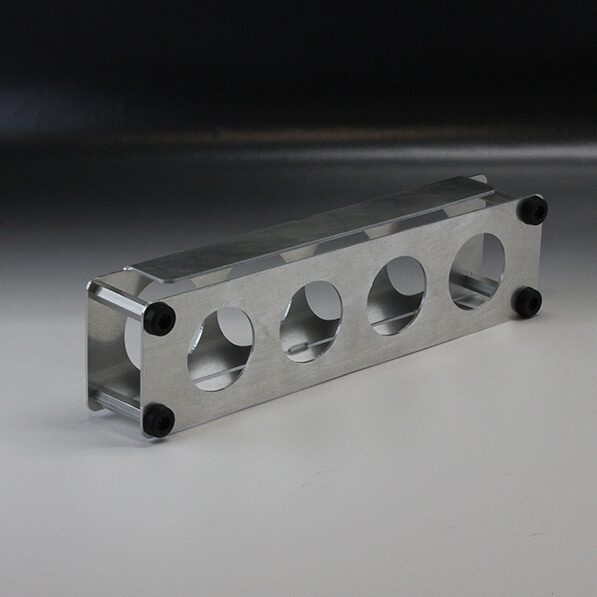

When it comes to aluminum CNC machining, working with non-ferrous metals like aluminum alloy and brass, you need a CNC machine that can handle more cut forces. ShopSabre CNC routers are built to deliver the cut forces needed to create impressive aluminum and brass products.

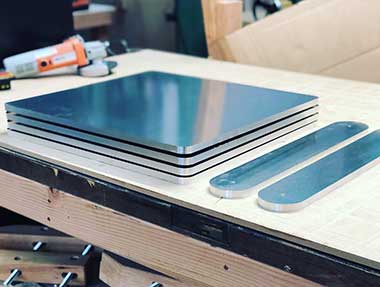

In CNC machining, aluminum alloys and grades are critical for ensuring product quality and performance. 5-axis CNC machining excels at achieving tight tolerances and producing complex shapes, while aluminum’s lightweight nature and versatility make it ideal for various applications.

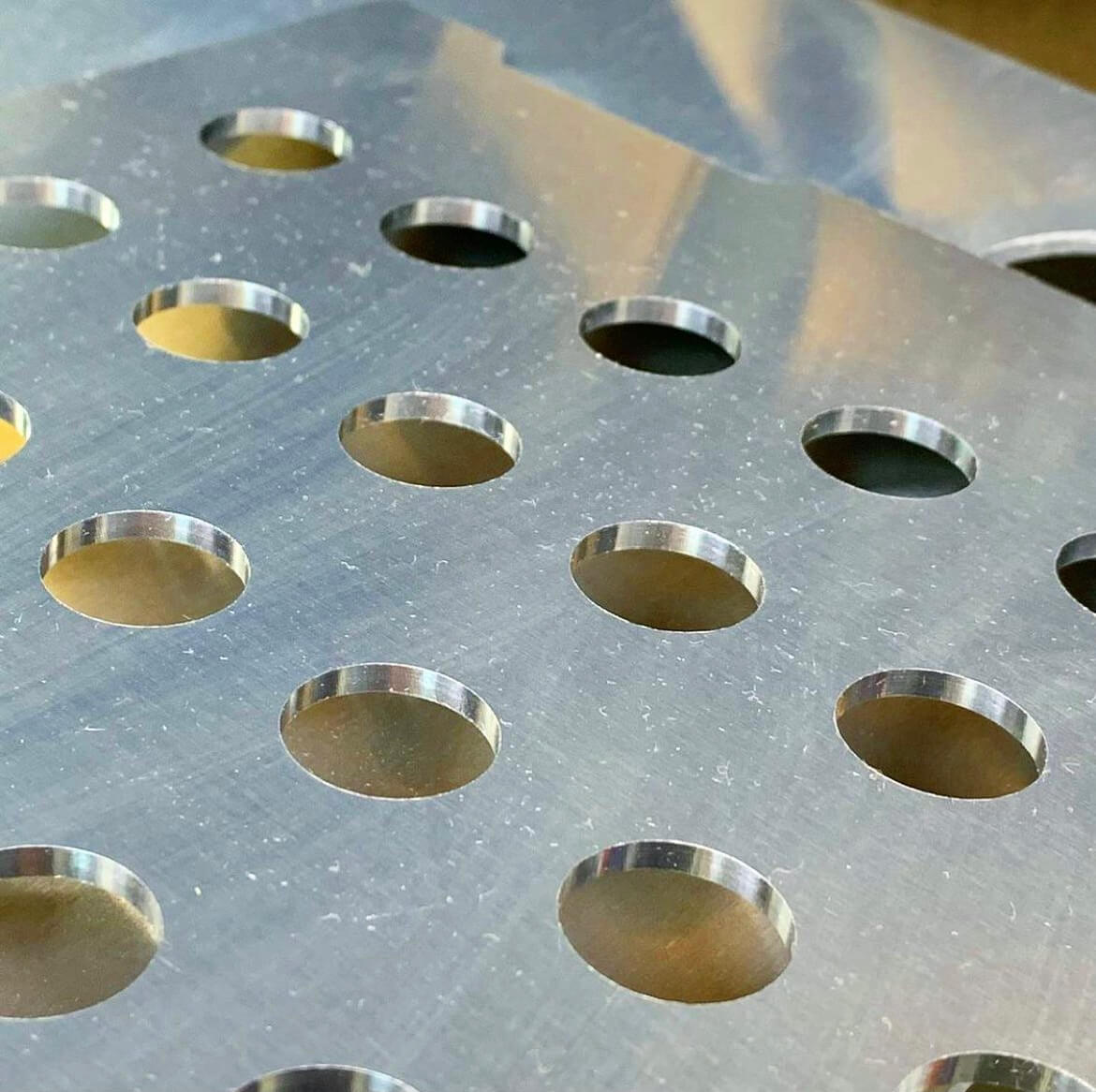

Using carbide tooling improves finish quality and reduces production costs. Aluminum’s natural corrosion resistance, particularly in marine and atmospheric conditions, further enhances its appeal. Precise cutting tools are essential for processes like turning, drilling, and milling to ensure optimal material removal and performance.

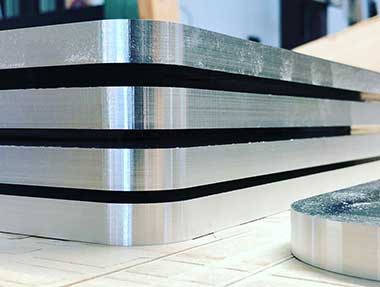

Heat-treated alloys such as T651 and T7351 provide increased strength and hardness, making them suitable for aerospace and automotive applications. Anodizing can further enhance aluminum’s protective oxide layer, improving wear and corrosion resistance for demanding environments.

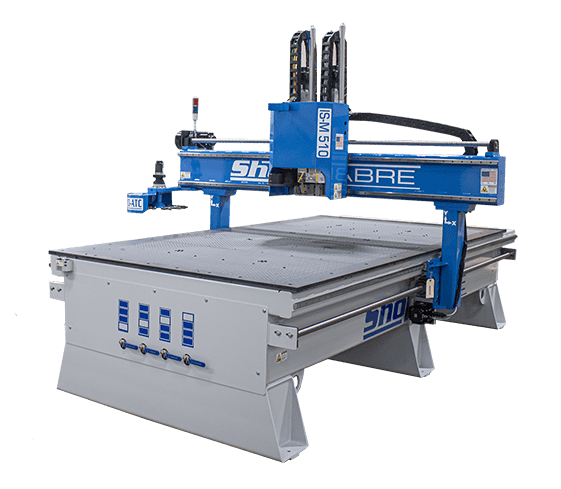

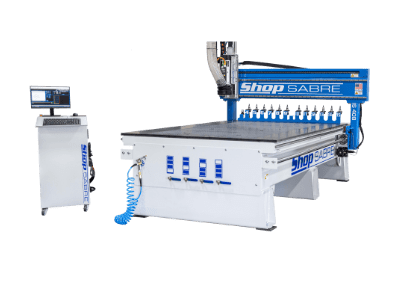

Industrial strength and customer service are the bedrock of a ShopSabre CNC router, perfect for brass and aluminum alloys

ShopSabre CNC machines are engineered to handle a wide range of materials, including heat-treated aluminum alloys like T651 and T7351, known for their enhanced strength and hardness in demanding applications.

Built to meet rigorous industrial standards, these machines ensure uninterrupted performance with minimal adjustments, excelling where other CNC systems fall short. Aluminum’s natural corrosion resistance, reinforced by protective oxide layers, reduces maintenance costs and extends machine longevity. Designed for durability and precision, ShopSabre CNC routers consistently deliver high-quality output, offering a reliable edge across various industries.

ShopSabre for your aluminum & brass machining needs

Built much heavier than the average CNC router, the industrial drive technology of a ShopSabre machine is similar to what you find in higher-cost milling centers and leaves you almost without limits.

With the correct tooling, a ShopSabre CNC router can easily tackle many of your non-ferrous material needs. Whether you are working with the most popular aluminum alloy, brass parts, aircraft aluminum, sign aluminum or plate aluminum, ShopSabre has the options necessary to perform your one-off, production, and nested manufacturing process. ShopSabre CNC routers excel in aluminum machining, making them ideal for machining aluminum with precision and accuracy. The use of carbide tooling enhances the quality of the finish and reduces production costs. Selecting the right cutting tool is crucial for achieving optimal results in various CNC machining processes.

Recommended CNC Machines

IS-M Series

Industrial Series (IS)

PRO Series

RC Series

ShopSabre 23

Questions?

Not sure which machine is right for you and your production? Schedule a free consultation with one of our in-house experts for personalized, one-on-one guidance.