Description

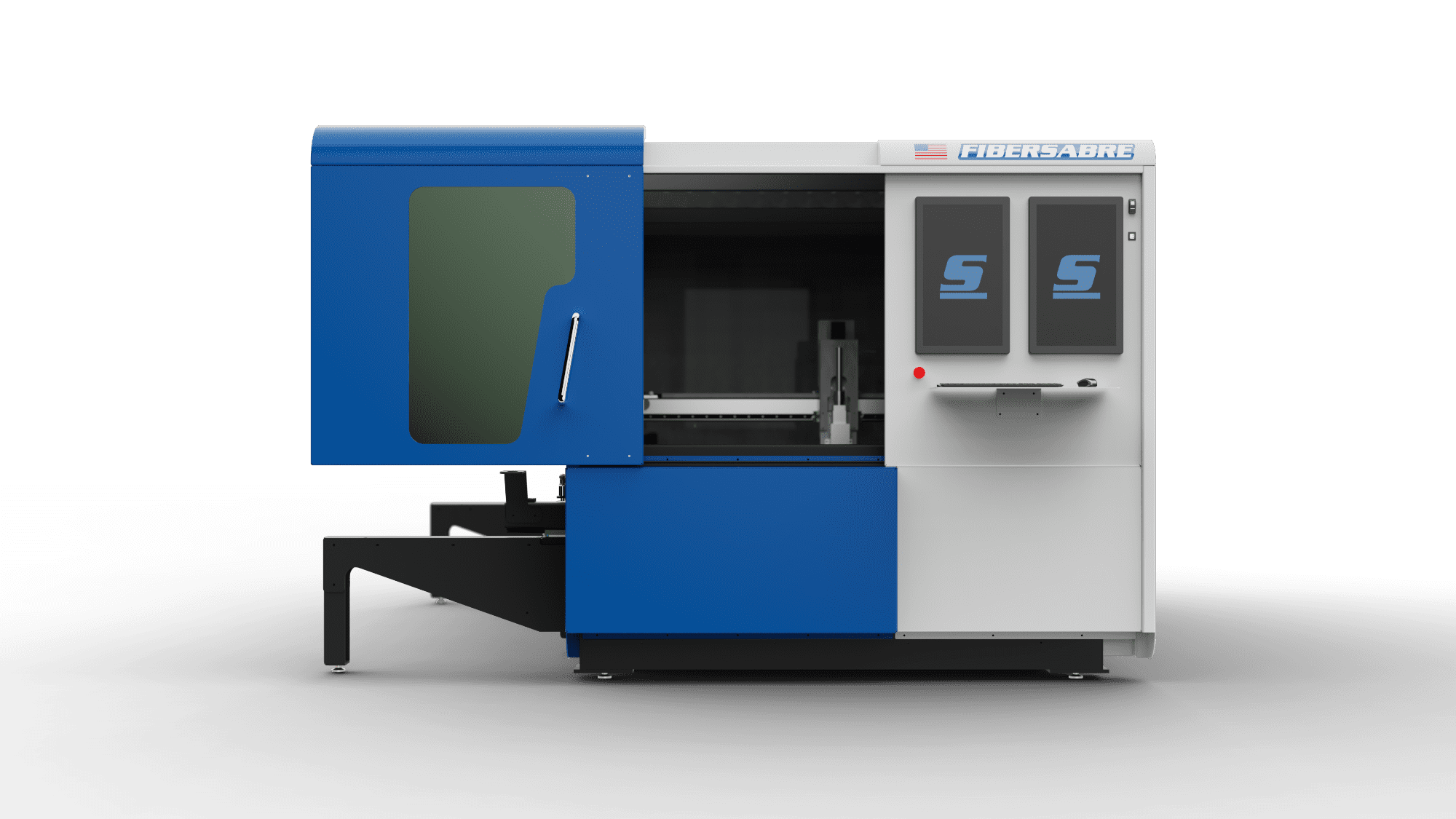

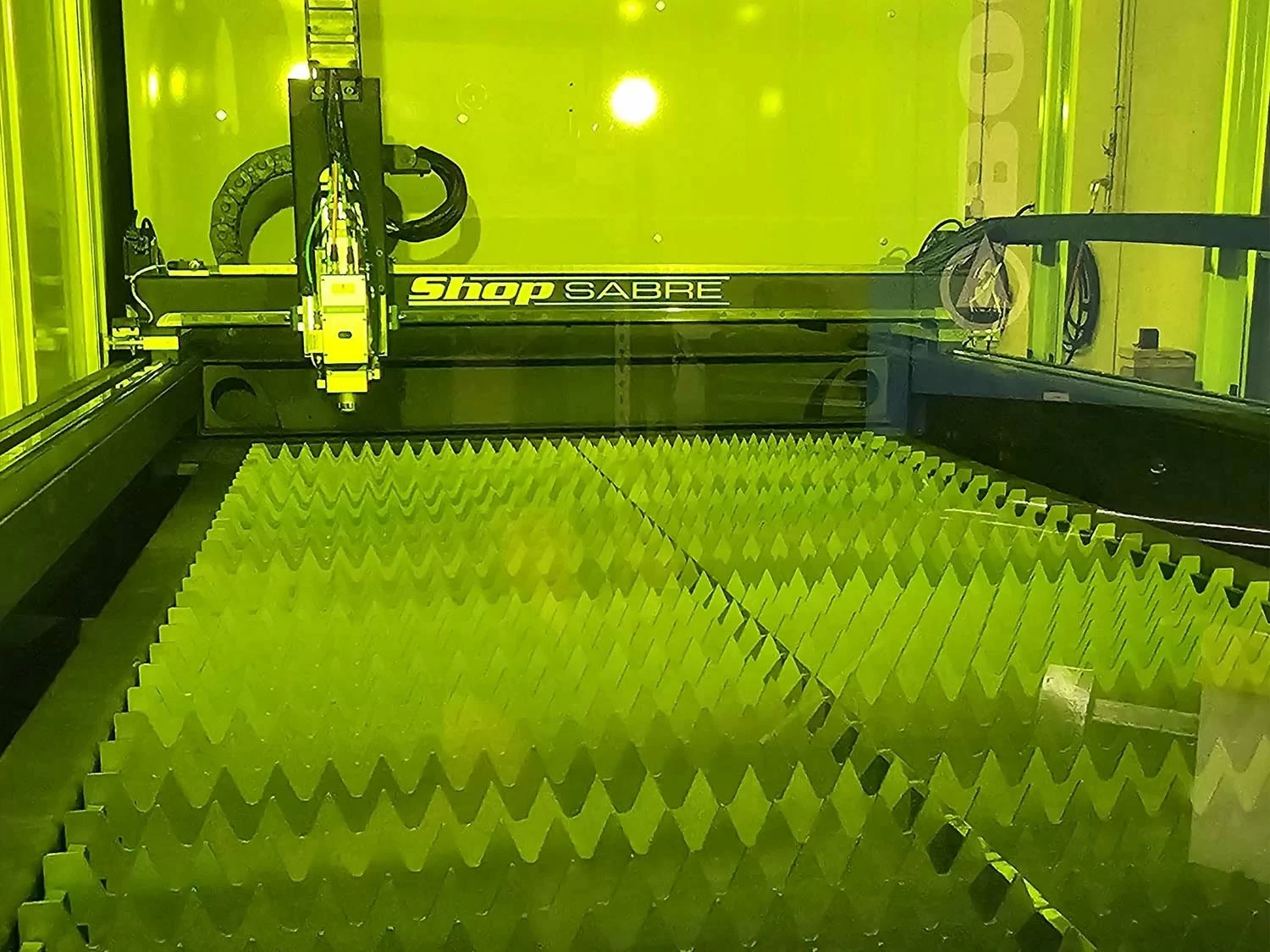

Introducing the NEW ShopSabre FiberSabre, the ultimate solution for precision and power in metal fabrication. Available in versatile 4’x8′ and 5’x10′ configurations, this machine is equipped with a 2kW fiber laser that effortlessly cuts through a wide range of metals, including steel, stainless steel, aluminum, copper, and brass, with unmatched accuracy and speed—all while operating on single-phase power for greater accessibility and ease of installation.

Designed with productivity and ease of use in mind, the FiberSabre features a material pull-out drawer, enabling seamless loading and unloading of materials, reducing downtime and ensuring a smoother workflow. Additionally, its clean-out drawers simplify routine maintenance, keeping your workspace clean and the machine running at peak performance.

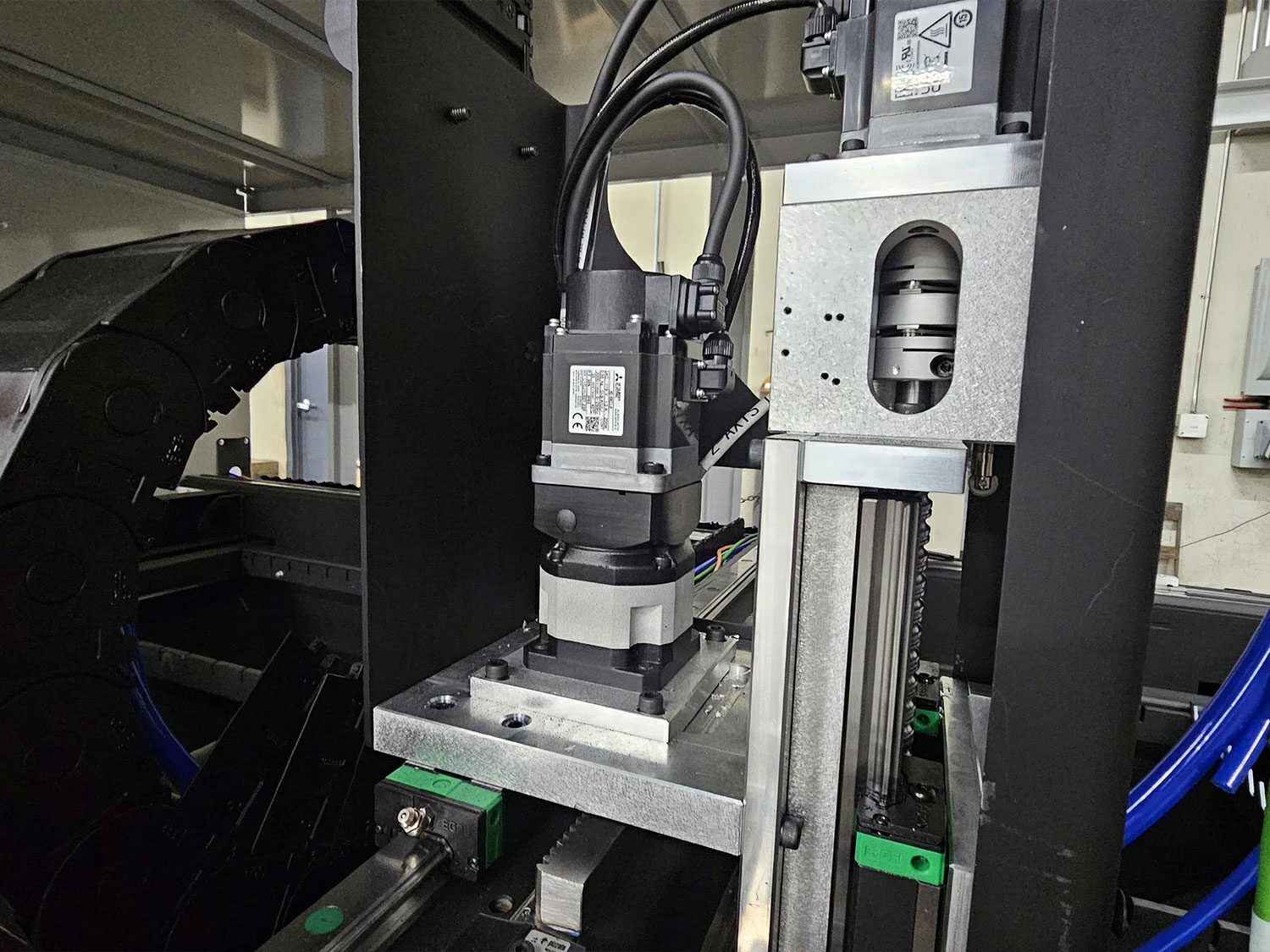

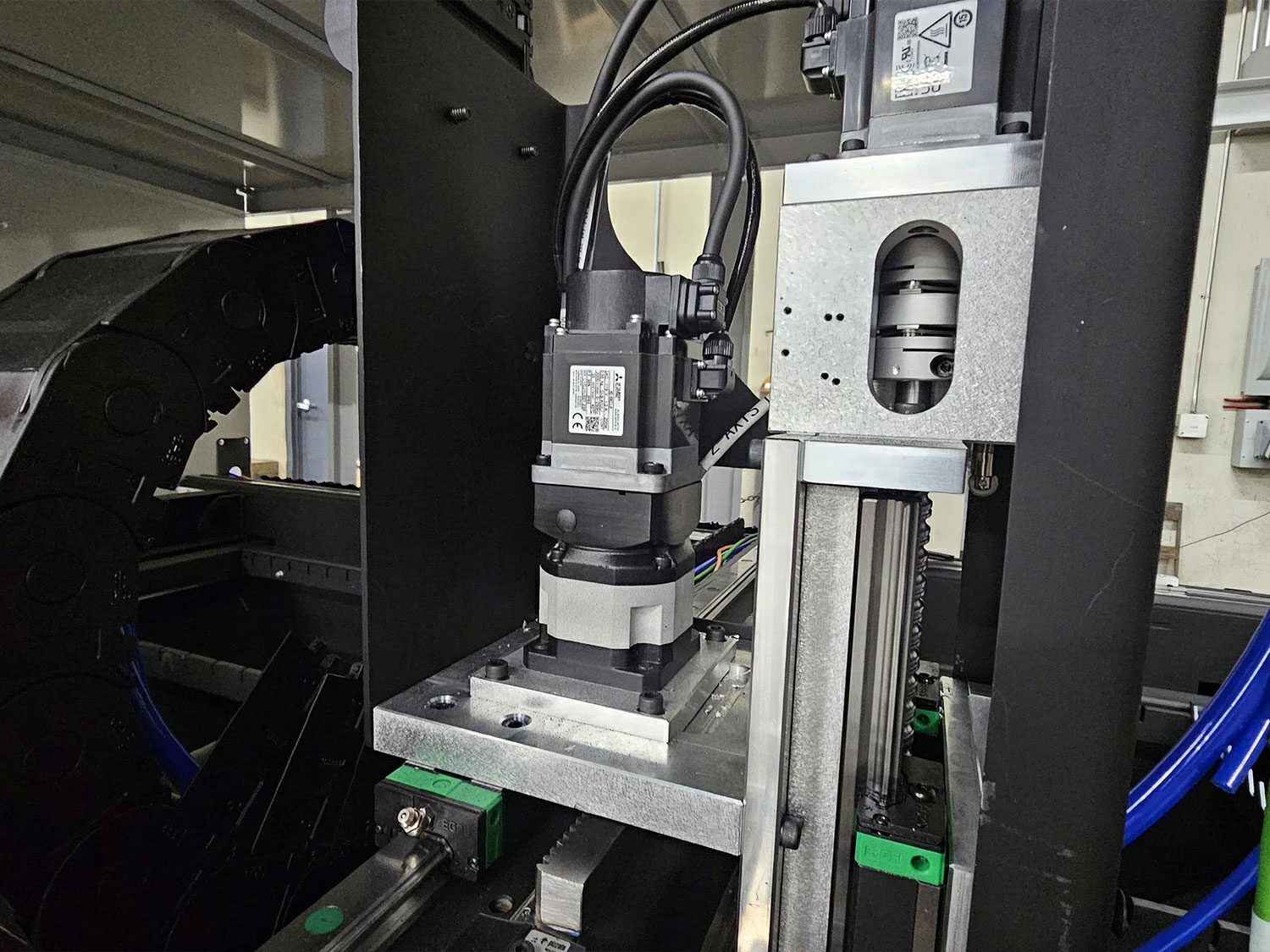

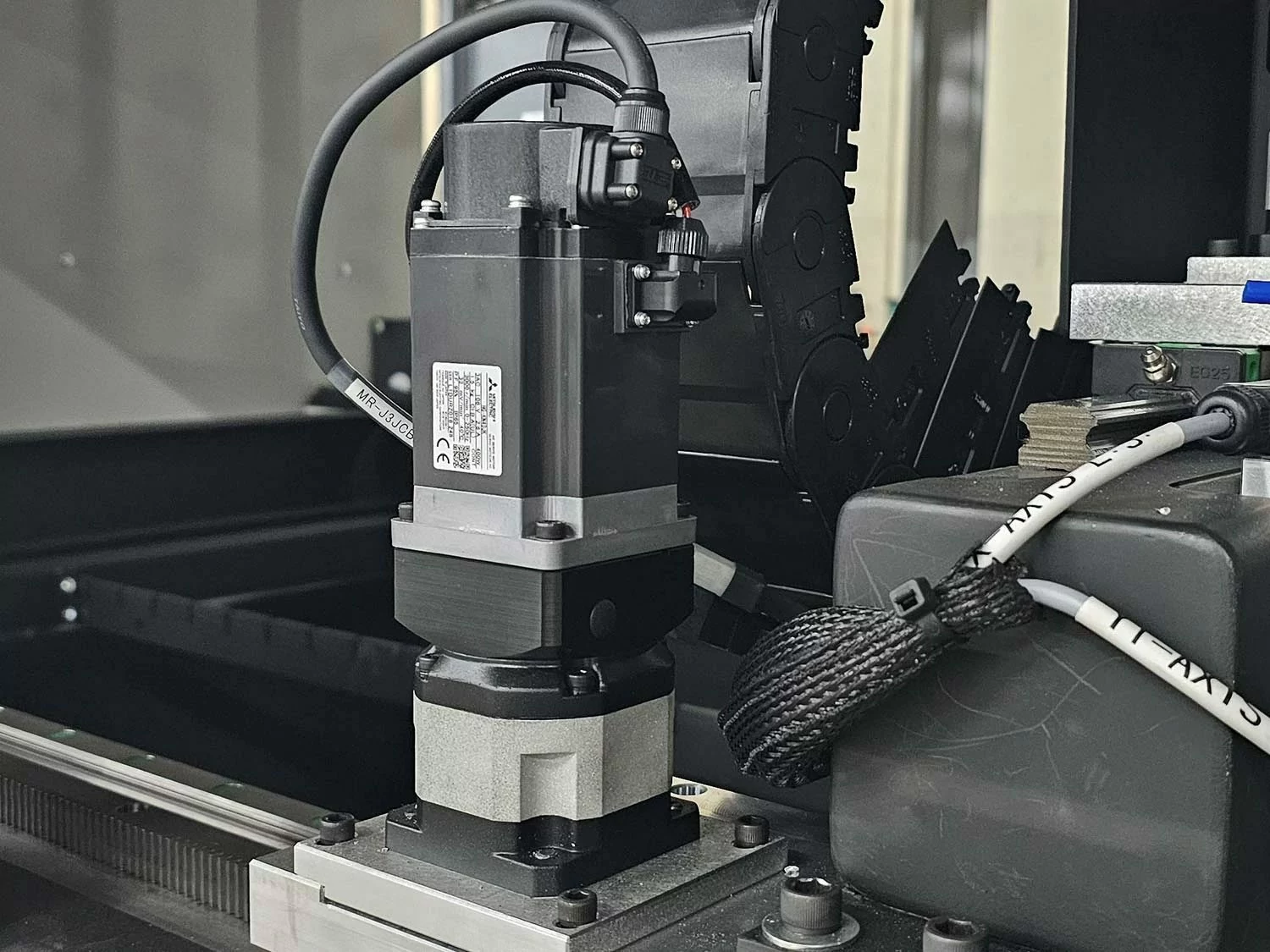

At the heart of the FiberSabre’s performance is its Mitsubishi AC Closed Loop Servo Technology, delivering precise, reliable movement control that minimizes errors and maximizes cutting quality. The entire setup is housed in a full safety enclosure, protecting operators by containing laser emissions and debris, ensuring a safe and efficient working environment.

With the ShopSabre FiberSabre, you’re investing in industry-leading technology that combines top-tier performance, user-friendly features, and the versatility of single-phase power, taking your capabilities and productivity to the next level.

Highlighted Features

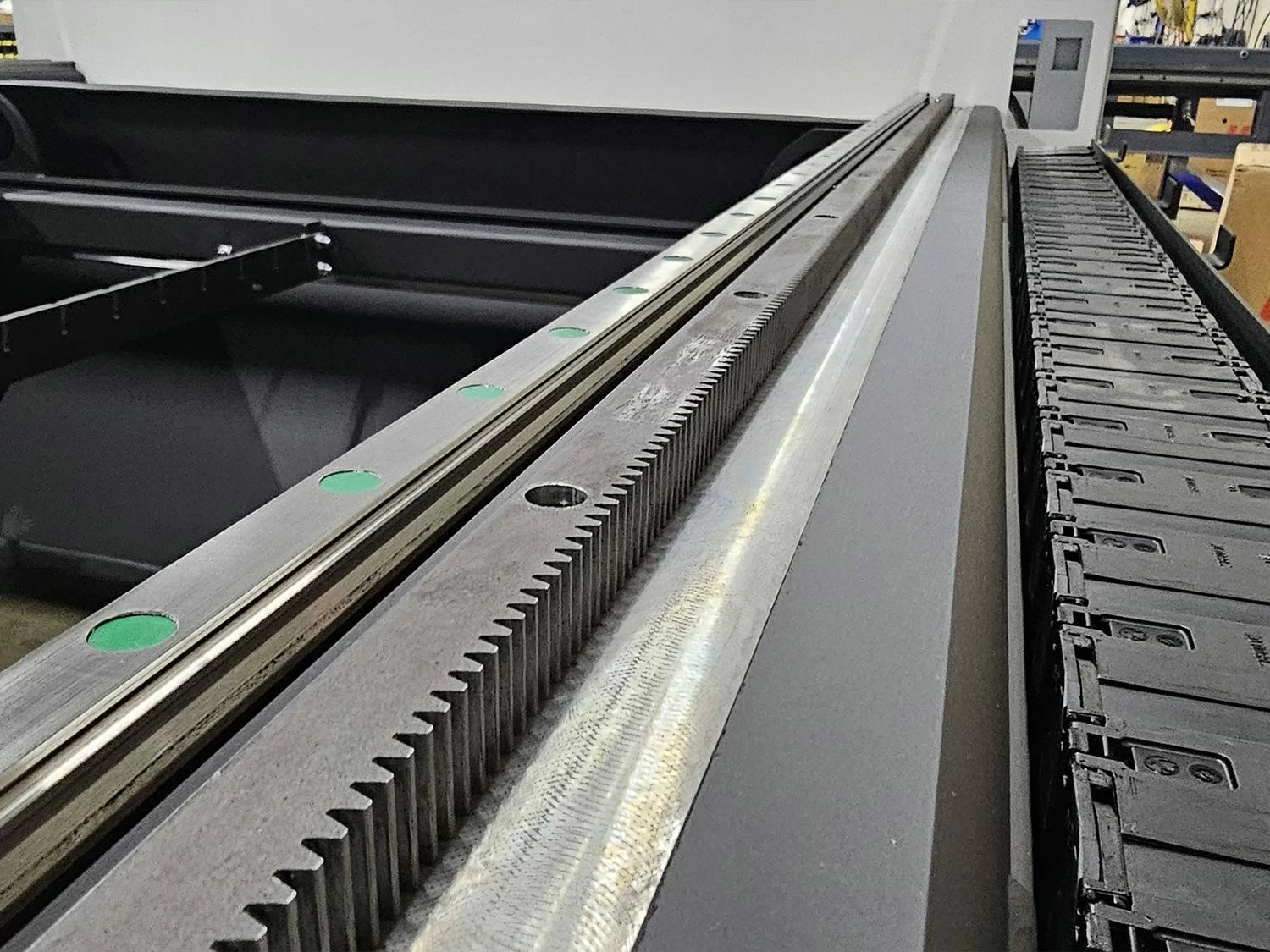

- Dual-Driven Y-Axis (Long Axis)

- Powered 100% by high-torque industrial brushless Mitsubishi AC digital closed-loop servo motors with encoder technology

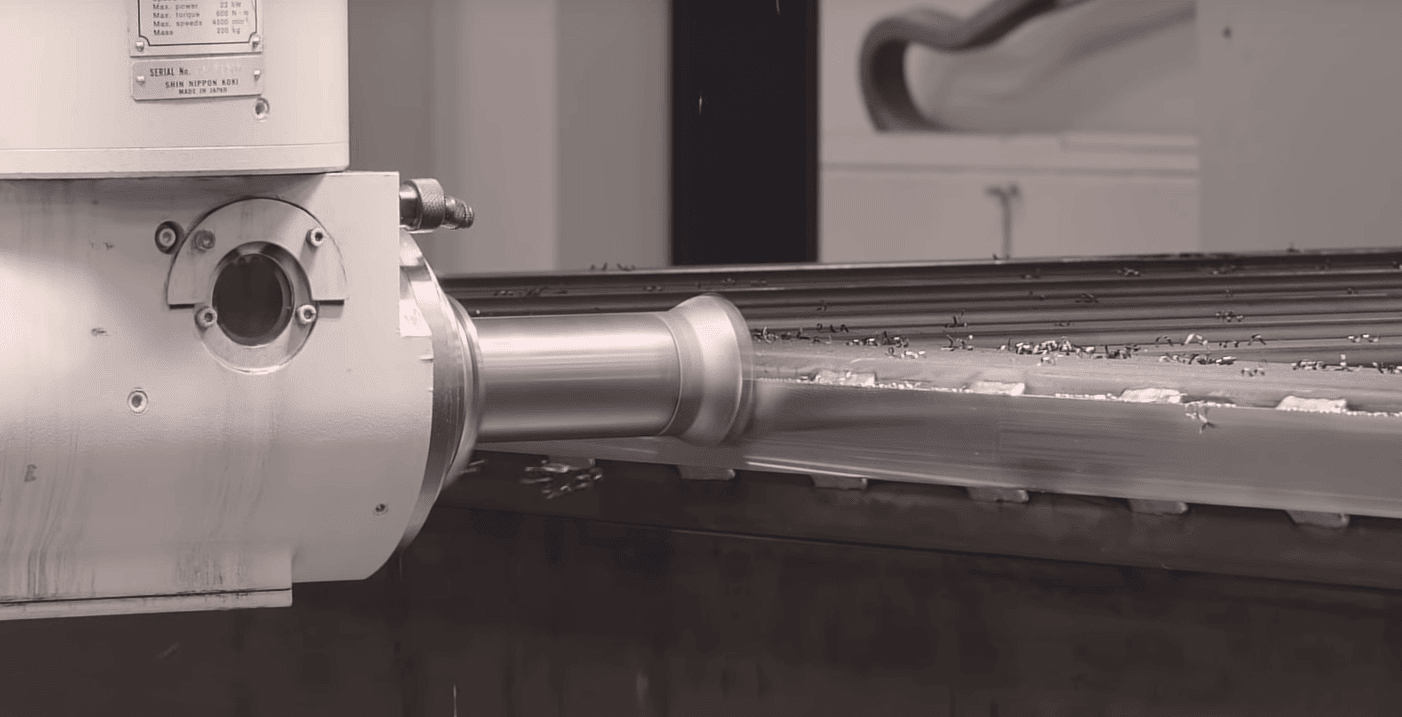

- Direct Drive Planetary Gear Reduction on the XY-axis

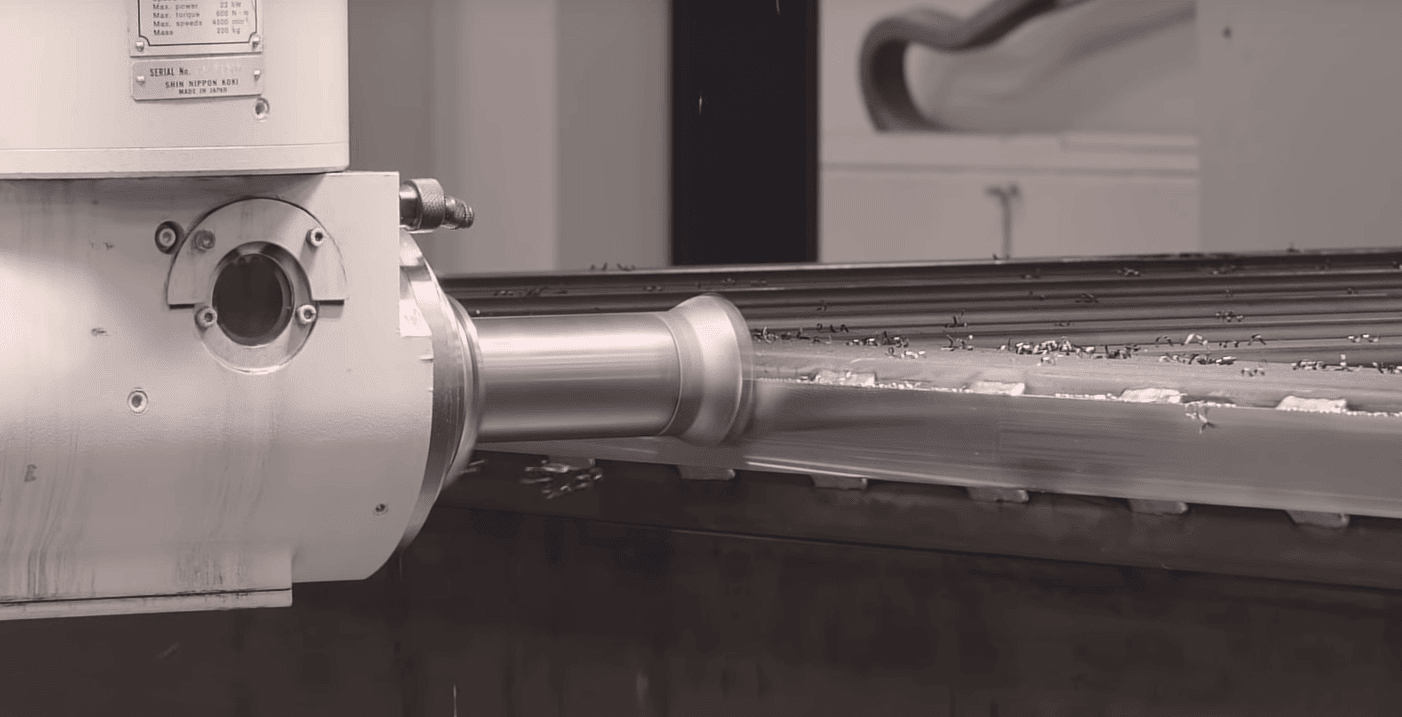

- Advanced Direct Drive Ball Screw for the Z-axis

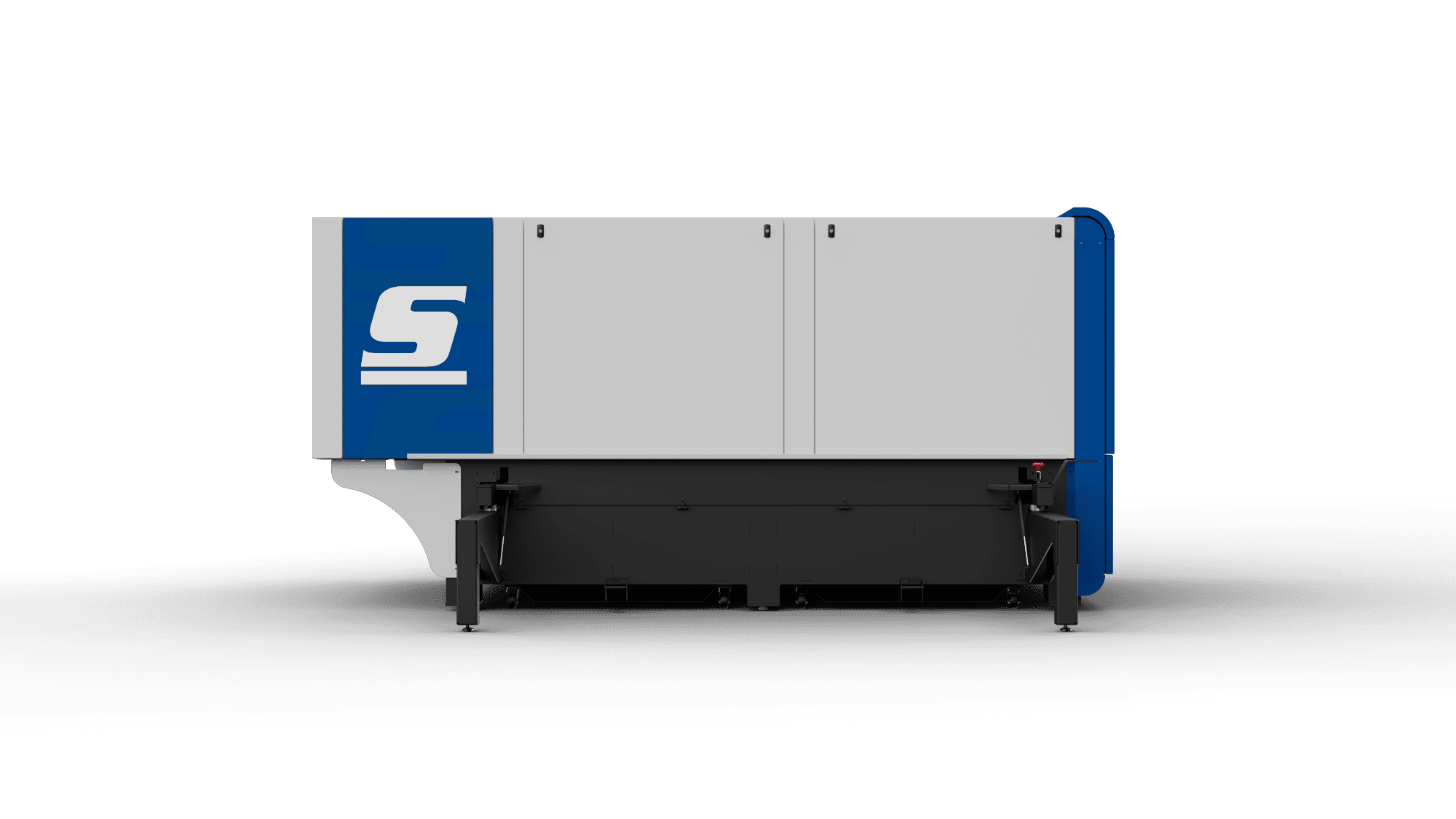

- Industrial welded, stress-relieved, and aerospace-milled structural steel tube gantry construction. Watch our steel vs aluminum video.

- Industrial structural steel tube welded, non-suspension-style frame with steel tube reinforcement for added stabilization and increased rigidity. No extruded aluminum, suspended table, or low-cost bolt-together designs.

- No assembly required

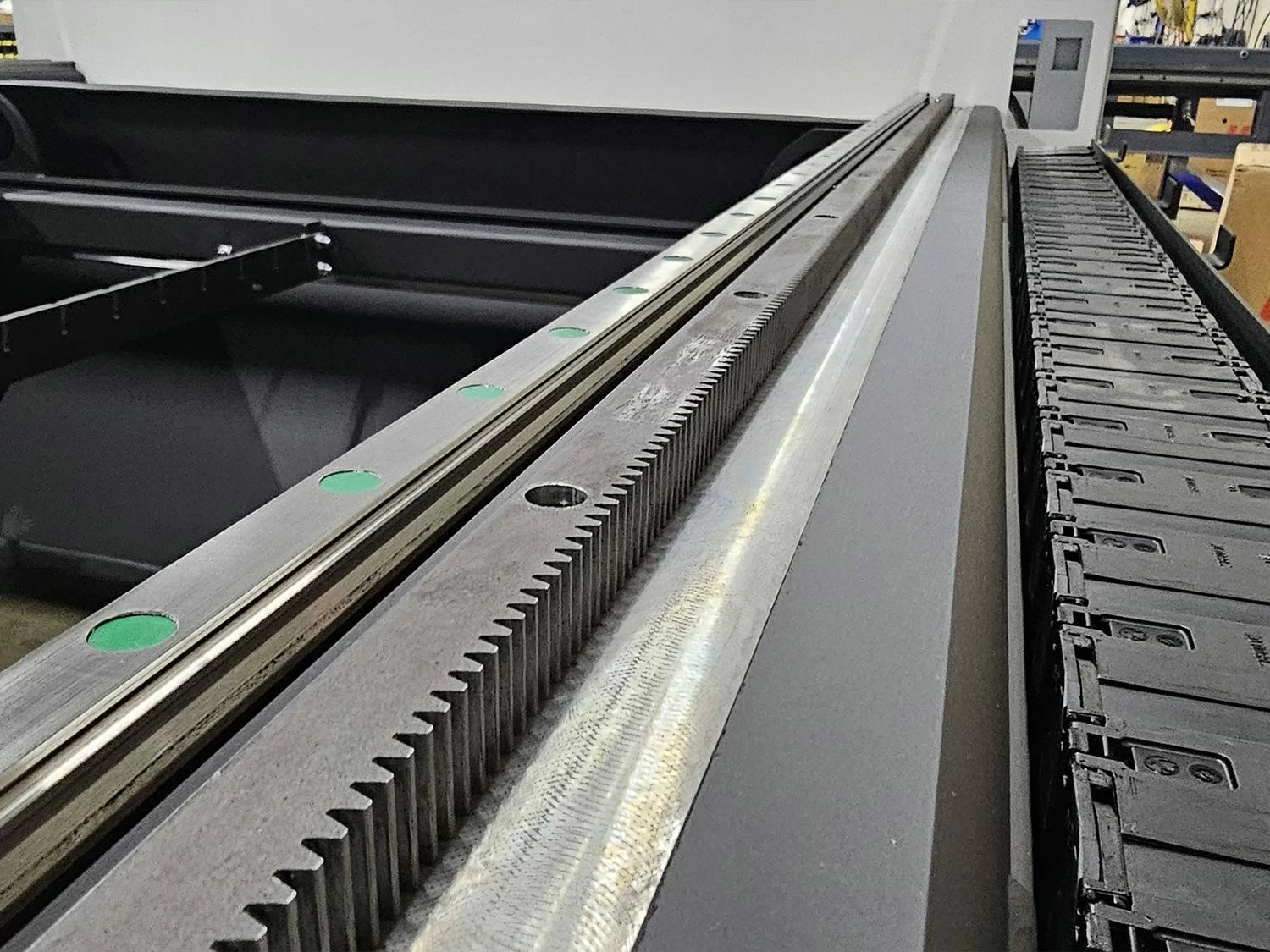

- High-performance 25mm linear profile guide rails and bearings with quad rollers on all axes

- ShopSabre exclusive low-maintenance inverted rack-and-pinion system to reduce maintenance and increase torque

- Collision-detection laser head with integrated advanced digital capacitance torch height control

- Industrial continuous flex robotic wiring with enclosed wire carriers for wiring protection and noise isolation

- Complete set of table slats with slat brackets installed at the factory

- Easy-to-learn software with point-and-click technology, including at-machine CAD/CAM capabilities

- Integrated laser cut charts with a pre-configured material library

- At-machine solid-state hard drive for easy job storage and dedicated high-speed multi-axis controller technology

- Includes tracing technology, as seen on PowerBlock TV Watch our search and restore video.

- Free SabreNation lifetime tech support via phone, email, and remote diagnostics Watch our support video.

- Free SabreNation lifetime training and SabreNation University access

- Included complete warranty

- Quick and effortless installation – machine ships fully assembled with no installation assistance required

- MADE IN THE U.S.A. — American manufactured and engineered using FEA software Watch our engineering video.

FiberSabre 2kW 408 |

FiberSabre 2kW 510 |

|

| Footprint | 134" x 147" x 76" | 146" x 186" x 76" |

| Cut Area | 49" x 97" | 61" x 121" |

| Z Clearance | 6.375" | 6.375" |

| Z Travel | 7.5" | 7.5" |

| Cutting Capacity | 5/8" - Laser Wattage Limited | 5/8" - Laser Wattage Limited |

| Repeatability | +/-.002" | +/-.002" |

| Rapid Traverse | 3500IPM | 3500IPM |

| Laser Power | 2KW | 2KW |

| Well Equipped | $64,995.00 | $74,995.00 |

| Get a Quote | Get a Quote | |

Finance for as low as $1,134.55/month |

Finance for as low as $1,309.11/month |

Questions?

Are you not sure which CNC machine is right for you and your production? Schedule a free consultation with one of our in-house experts for personalized, one-on-one guidance.

FiberSabre 2kW Features

Industrial Precision Frame

FiberSabre 2kW Features

AC Digital Servo Motors

FiberSabre 2kW Features

Advanced Drive Technology

FiberSabre 2kW Features

Aerospace Milling Technology

FiberSabre 2kW Features

Industrial Z Axis Technology

FiberSabre 2kW Features

Industrial Precision Frame

FiberSabre 2kW Features

AC Digital Servo Motors

FiberSabre 2kW Features

Advanced Drive Technology

FiberSabre 2kW Features

Aerospace Milling Technology

FiberSabre 2kW Features

Industrial Z Axis Technology

FiberSabre 2kW Details

Finance Calculator

Finance Calculator