Description

The CNC Machine That Professionals Trust

The PRO Series CNC router lineup is our most popular, offering significant upgrades in technology, durability, and cutting force.

Built to outperform every comparably priced CNC machine on the market, the PRO Series is equipped with top-of-the-line components and advanced technology typically found in machines costing $80,000 or more. When paired with our free lifetime technical support and American-made construction, no other CNC machine delivers more value.

The PRO Series features an oversized heavy-duty structural tube steel frame, a robust gantry, and structural tube steel gantry uprights. It also incorporates an industrial anti-backlash ball screw drive system on every axis. Whether you’re performing nested-based sheet work, crafting MDF doors, or handling one-off custom machining, the PRO Series ensures precise, high-quality results every time.

With its oversized working area, the PRO Series accommodates various projects and materials, including 5×5 processing on the 4×8 CNC router and 5×10 CNC router systems.

Ideal for manufacturing, furniture production, cabinetry, signage, R&D, and even at-home use, the PRO Series is engineered to elevate your production to the next level.

Contact us today to learn more about the ShopSabre PRO Series CNC routers.

Highlighted Features

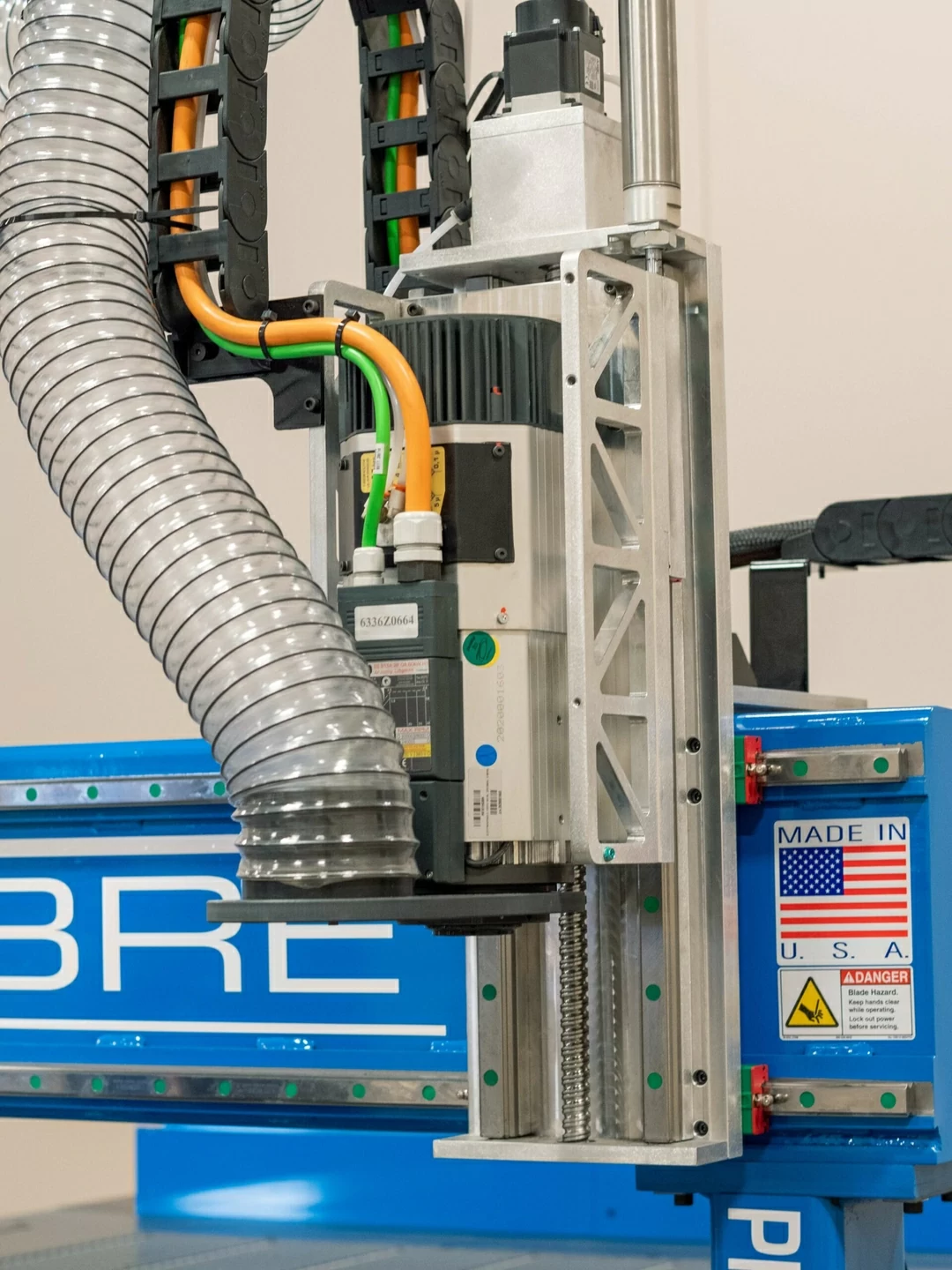

- Italian HSD Electric Fan-Cooled Spindle, available in single-phase or three-phase operation, with or without Auto Tool Changer (ATC) option (100% duty-rated).

- Powered 100% by ball screw drive systems with a dual-driven Y-axis (long axis) and ShopSabre Anti-Whip Technology. Watch our ball screw video.

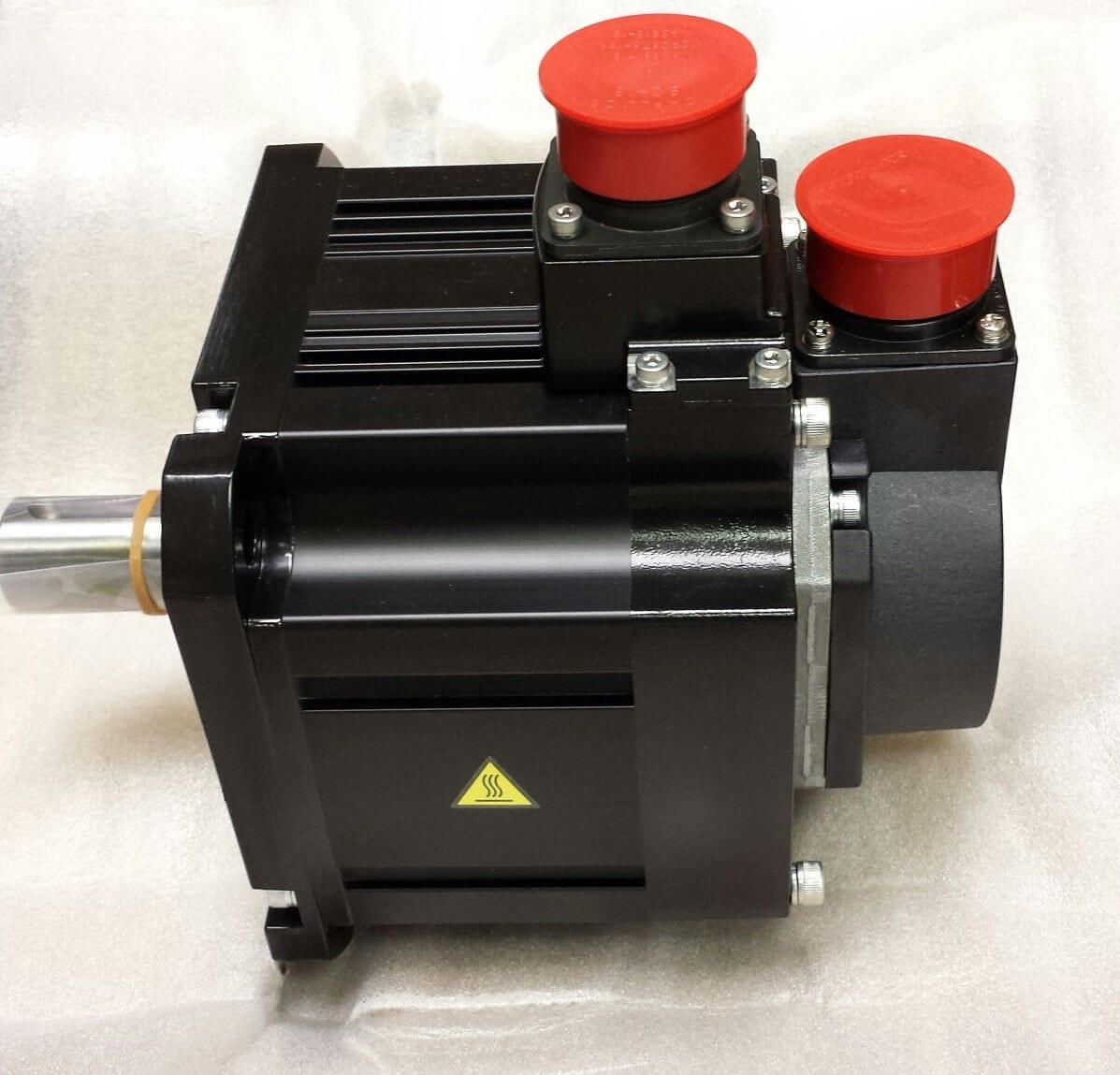

- Industry-leading components, including industrial digital AC closed-loop brushless servo motors with glass encoder technology and individual drive amplifiers with digital tuning. Watch our top servo motor technology video.

- Industrial welded, stress-relieved, and aerospace-milled structural steel tube frame construction. Watch Aerospace Milling of Frames.

- Industrial structural steel tube gantry uprights and steel cross bridge with milled mating surfaces. Watch our steel vs aluminum video.

- High-performance 25mm linear profile guide rails and bearings with quad rollers on all axes. Watch our linear guide rails video.

- ShopSabre State-of-the-Art Tool Measure Technology. Watch our tool measure video.

- ShopSabre Reinforced Z-Axis Technology, featuring tool plate stiffeners and optional Super Z Technology.

- Quick Release Dust Skirt Technology (ask about Dust Dock Technology for ATC systems). Watch Dust Dock Videos.

- Vectric VCarve PRO CAD/CAM Full License Software.

- Easy-to-learn software with point-and-click technology, including at-machine CAD/CAM abilities. Watch our control screen video.

- At-machine solid-state hard drive for easy job storage and a dedicated high-speed multi-axis controller.

- Machine Operator Control Tower, with auto-leveling feet and an included PC system featuring full networking and file management via USB and internet connectivity.

- Free SabreNation Lifetime Tech Support via phone, email, and remote diagnostics. Watch our support video.

- Free SabreNation Lifetime Training and SabreNation University Access! Get Your CNC Education.

- Included Complete Warranty.

- Quick and effortless installation – machine ships fully assembled with no installation assistance required.

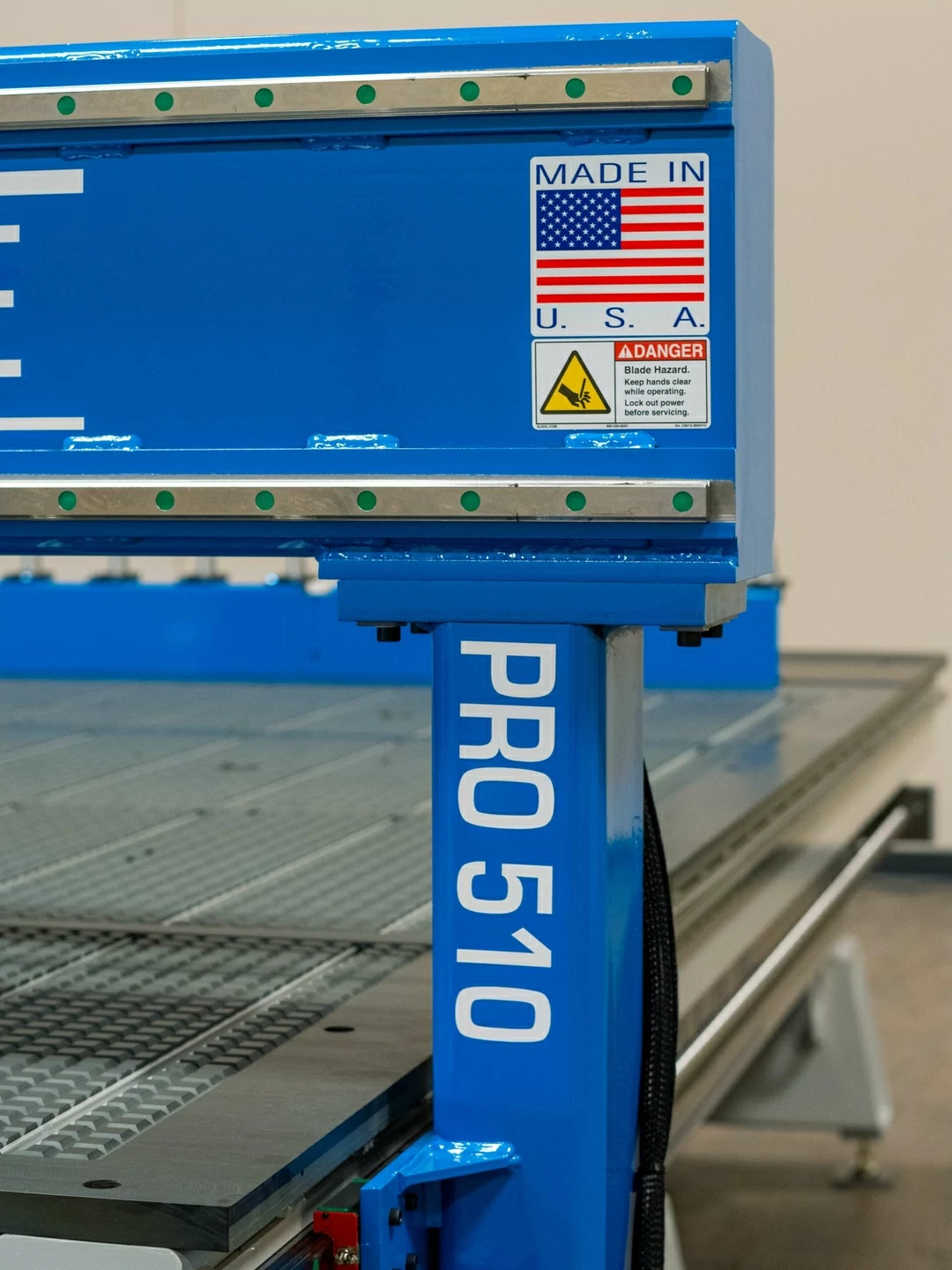

- MADE IN THE U.S.A. – American manufactured and engineered using FEA software. Watch our engineering video.

- Grow with your business by expanding options to meet your exact needs. Watch our expansion equipment video.

Well Equipped

Includes:

- Aerospace-milled welded structural steel frame & structural steel gantry bridge with steel tube uprights

- 3-axis ball screw drive technology with ShopSabre Twin Screw Anti-Whip Technology on the Y-axis

- 25MM linear guide rails & bearings on all axes

- Ethernet/network-ready machine controller with at-machine PC & Windows OS

- Vectric VCarve PRO CAD/CAM software license

- AC digital closed-loop servo motors with absolute encoder technology & individual amplifiers with an alarm system

- Automation control of spindle via G-code & control system

- Professional wire management system

- Dust boot with 4” port

- Limit switches and boundary sensing

- Emergency stop

- Auto tool measuring touch pad

- Auto Z-height measuring touch pad

- Surfaced phenolic hi-flow vacuum-ready tabletop with 4 independently controlled zones

- 5HP/6HP HSD electric fan-cooled Auto Tool Changer with 6 tool positions, including 6 ISO30 tool holders & ER32 collets

- Tool rack, tool chuck, collet wrenches & VFD for single-phase or three-phase operation

- Industrial table reference pins (pop-up pins)

- Machine maintenance kit

- ShopSabre SabreNation support (phone, email, remote connectivity) for the life of the original owner

- SabreNation training & university access for the life of the original owner

Some items may be able to be removed or modified depending on needs

PRO 404 |

PRO 408 |

PRO 510 |

|

| Footprint | 80" x 85" x 93" | 80" x 133" x 93" | 93" x 156" x 93" |

| Cut Area | 60" x 50" x 12" | 60" x 100" x 12" | 72" x 125" x 12" |

| Z Clearance | 12" standard | 12" standard | 12" standard |

| Z Travel | 16" | 16" | 16" |

| Rapid Speed | 1200IPM | 1200IPM | 1200IPM |

| Repeatability | +/-.001" | +/-.001" | +/-.001" |

| Drive Motors | AC Servo Motors | AC Servo Motors | AC Servo Motors |

| Drive System | Ball Screw X, Dual Y, & Z axis | Ball Screw X, Dual Y, & Z axis | Ball Screw X, Dual Y, & Z axis |

| Well Equipped | $39,495.00 | $41,995.00 | $45,995.00 |

| Get a Quote | Get a Quote | Get a Quote | |

Finance for as low as $689.42/month |

Finance for as low as $832.51/month |

Finance for as low as $802.89/month |

Questions?

Are you not sure which CNC machine is right for you and your production? Schedule a free consultation with one of our in-house experts for personalized, one-on-one guidance.

PRO Series CNC Router Features

Industrial Precision Frame

ShopSabre CNC frames are FEA-engineered and tested. Created here in Lakeville, Minnesota, they are constructed from massive, oversized structural tube steel, aerospace milled for accuracy, and welded for rigidity. Our stacked and welded design adds rigidity, providing more floor contact and better vibration control. Internally, the large tubes are cross-braced and stiffened to increase lateral rigidity.

PRO Series CNC Router Features

Digital A/C Servo Motors

ShopSabre PRO Series machines come standard with AC digital closed-loop servo motors for higher speeds, greater accuracy, and less maintenance. Self-monitoring glass encoder technology provides extreme performance, delivering some of the top-rated servo technology in the world!

PRO Series CNC Router Features

Aerospace Milling Technology

ShopSabre CNC frames are processed through some of the world’s most advanced methods to ensure accuracy, including precision milling of contact surfaces for bearing and rail placement, as well as ball screw mounts. A machine can only be as accurate as its foundation, so the frame on a ShopSabre is built to a tolerance above the competition.

PRO Series CNC Router Features

Ball Screw Technology

ShopSabre PRO machines come standard with 3-axis ball screw drives. The Y-axis (long axis) features twin screws, providing 7 times more rigidity than competing machines and unprecedented performance. ShopSabre’s ball screw technology offers less backlash than rack and pinion and, thanks to our Whip-Free technology, increases cutting accuracy and delivers superior edge finishes. This ball screw technology can outlast most comparable machines by as much as 3 to 4 times, with very little maintenance required.

PRO Series CNC Router Features

Vacuum Performance

The Vacuum Option on the ShopSabre PRO Series gives you quick and easy brass lever zone controls with integrated hard pipe connection for increased air flow and the reserve tank built into the frame to ensure your vacuum stays consistent!

PRO Series CNC Router Features

Industrial Precision Frame

ShopSabre CNC frames are FEA-engineered and tested. Created here in Lakeville, Minnesota, they are constructed from massive, oversized structural tube steel, aerospace milled for accuracy, and welded for rigidity. Our stacked and welded design adds rigidity, providing more floor contact and better vibration control. Internally, the large tubes are cross-braced and stiffened to increase lateral rigidity.

PRO Series CNC Router Features

Digital A/C Servo Motors

ShopSabre PRO Series machines come standard with AC digital closed-loop servo motors for higher speeds, greater accuracy, and less maintenance. Self-monitoring glass encoder technology provides extreme performance, delivering some of the top-rated servo technology in the world!

PRO Series CNC Router Features

Aerospace Milling Technology

ShopSabre CNC frames are processed through some of the world’s most advanced methods to ensure accuracy, including precision milling of contact surfaces for bearing and rail placement, as well as ball screw mounts. A machine can only be as accurate as its foundation, so the frame on a ShopSabre is built to a tolerance above the competition.

PRO Series CNC Router Features

Ball Screw Technology

ShopSabre PRO machines come standard with 3-axis ball screw drives. The Y-axis (long axis) features twin screws, providing 7 times more rigidity than competing machines and unprecedented performance. ShopSabre’s ball screw technology offers less backlash than rack and pinion and, thanks to our Whip-Free technology, increases cutting accuracy and delivers superior edge finishes. This ball screw technology can outlast most comparable machines by as much as 3 to 4 times, with very little maintenance required.

PRO Series CNC Router Features

Vacuum Performance

The Vacuum Option on the ShopSabre PRO Series gives you quick and easy brass lever zone controls with integrated hard pipe connection for increased air flow and the reserve tank built into the frame to ensure your vacuum stays consistent!

PRO Series CNC Router Details

Finance Calculator

Finance Calculator