Everything You Need in a CNC Plasma

The two most critical components of any CNC plasma system are service and quality. You need a machine that consistently delivers high-performance results. At ShopSabre CNC, we prioritize unmatched build quality, cutting-edge technology, and industry-leading customer service—ensuring long-term reliability and lasting value.

CNC plasma machines are a significant investment. While it may be tempting to choose cheaper Chinese imports, bolt-together designs, aluminum frames, or DIY kits, these low-cost alternatives often come with inferior components and outdated technology. The result? Frequent breakdowns, reduced precision, and expensive replacements. That’s why we always say: “Buy your second machine the first time.” Avoid the headaches, hidden costs, and downtime that come with low-quality equipment.

More people trust ShopSabre CNC than any other manufacturer thanks to our superior quality, competitive pricing, and proven reliability. Every month, more customers upgrade from other brands to ShopSabre—our reputation speaks for itself.

Below, we break down the key components of a CNC plasma system to show why ShopSabre delivers the best performance and value on the market. Compare our machines to higher-priced systems, and you’ll quickly see why ShopSabre is the smart choice.

Framework

Framework

Structural Steel Construction

ShopSabre CNC plasmas are built from top-rated North American structural steel tubing and heavy-wall steel plate. We never use fabricated tubes (bent steel), extruded aluminum, folded sheet metal, or angle iron in our machine frames. At ShopSabre, we understand that poor frame design impacts cut quality—and that’s not something we accept in the tools we buy, let alone the machines we build and put our name on.

Our CNC plasma systems are engineered as production-grade, fully welded steel structures—no bolt-together assembly required. It’s the same construction approach you’ll find on machines retailing for $100,000 or more. There’s a reason bridges are made from steel and not aluminum—and we apply that same logic to deliver the strength and durability your plasma system demands.

Unbeatable Precision, Accuracy, and Strength

The frames on ShopSabre CNC plasma machines are designed and built to handle even your toughest jobs—without needing daily bolt tightening or squaring like lower-quality machines. This means you get the most rigid and accurate assembly in its class.

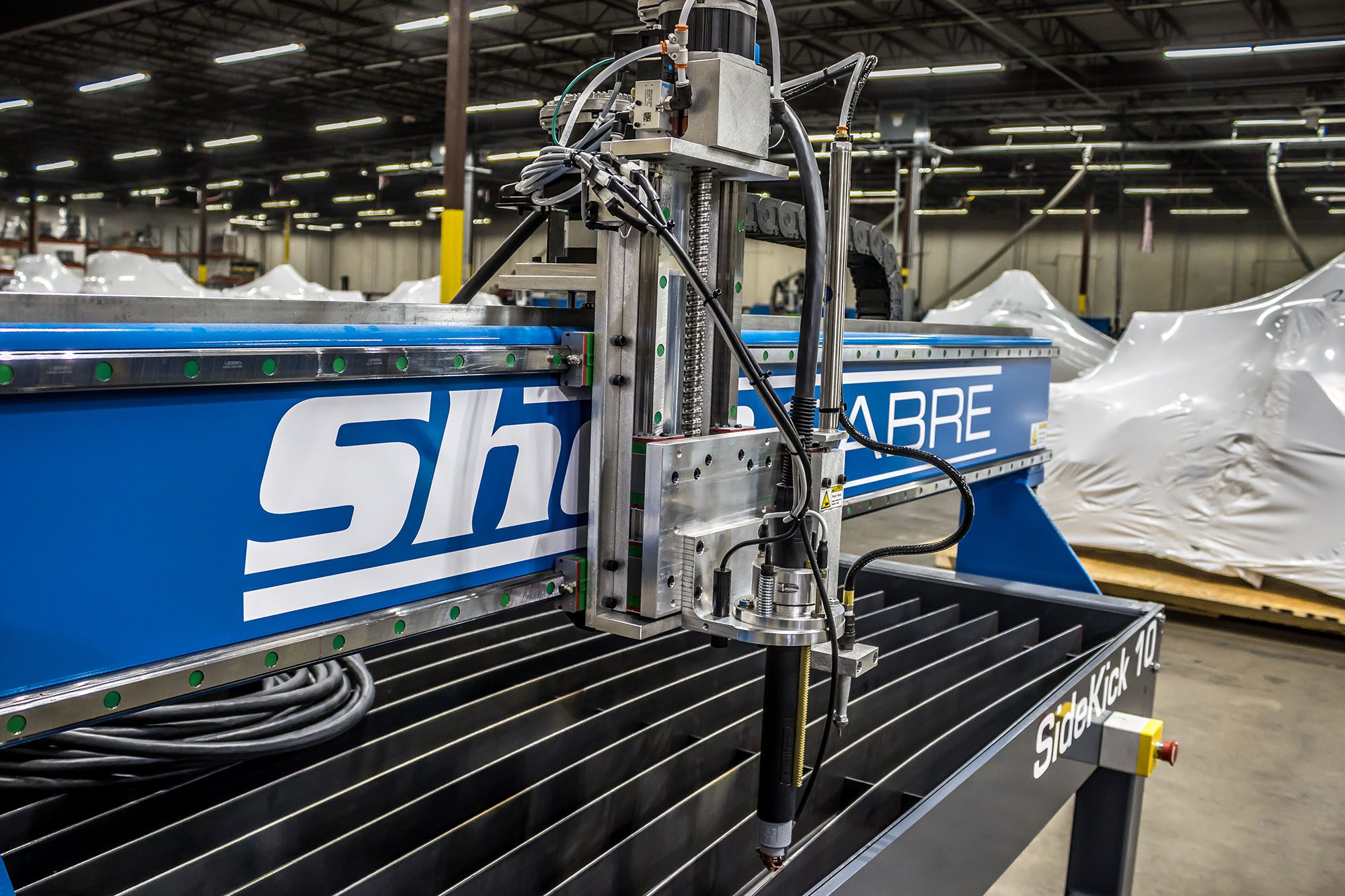

We precision-mill all structural components to eliminate tolerance issues before your machine even ships. For example, our ShopSabre SideKick CNC Plasma features steel tube legs cross-braced in both directions, so you can confidently load heavy plate material without worrying about table collapse. Every SideKick model includes a minimum of six legs, providing support at each corner and in the center of the machine.

Our ShopSabre ShopMaster Plasma systems take it even further, transferring all weight directly to the floor using braced tube steel and a solid plate steel shell—no suspended weight, no shortcuts. And we don’t use flimsy covers or cosmetic panels to hide the frame—our strength is on full display.

ShopSabre machines consistently outweigh and outlast the competition. Don’t settle for a machine that’s bolted together or cobbled from off-the-shelf parts. Our frames are engineered with zero compromise. With over 20 years of experience, ShopSabre machines are built to evolve with your business and stand the test of time.

Gantry Construction

Gantry Construction

Industrial Construction

Whether you choose the ShopSabre SideKick or the ShopMaster Series, we never pair an industrial frame with a lightweight gantry and call it done. Every ShopSabre CNC plasma cutter comes standard with a structural tube steel gantry that’s precision-milled and stress-relieved for maximum durability.

Our gantries are engineered using the same advanced FEA (Finite Element Analysis) software we use for our machine frames—ensuring ideal bearing spacing, tube sizing, and wall thickness for the machine’s workload. In fact, the ShopSabre SideKick and ShopMaster PRO Series plasmas all use the same gantry design found in high-production tables that retail for over $100,000.

At ShopSabre, we go above and beyond by pairing industrial-grade frames with industrial-strength steel gantry bridges. This lets you push your CNC plasma machine harder and faster, without worrying about the deflection and inaccuracy common with lighter gantries found on competitor models. We sweat the small stuff—because that’s what delivers the precision you need.

Built to Withstand Heat

When you’re cutting steel with plasma or flame, you’re generating extreme heat—and that heat rises directly into the gantry bridge again and again. Machines using lightweight, thin-walled steel or aluminum gantries begin to warp and deflect over time, degrading precision as the metal repeatedly expands and contracts.

ShopSabre CNC gantries are constructed from structural tube steel and engineered using FEA software to maintain strength and precision under heat. We design our systems with a minimum 8” gantry clearance, allowing heat to dissipate efficiently and reducing thermal impact on the gantry itself.

Why does it matter? Because aluminum has a heat tolerance of around 1,266°F, while steel can handle temperatures up to 2,500°F. More steel means less warping, less heat soak, and more years of reliable performance.

It’s no surprise that all high-production CNC plasma machines use steel gantry designs—and so do we.

Motion Components (Drives, Guides, and Motors)

Motion Components (Drives, Guides, and Motors)

High-Precision Components

ShopSabre CNC plasma systems are built using high-precision components throughout. We use the same 25mm linear guide rails with quad roller sets and triple-wiper linear bearing blocks found on high-end CNC mills and large-scale plasma tables. Each axis features two linear guide rails, each with two bearing blocks, ensuring that cutting forces are evenly distributed. This design reduces wear, noise, and vibration while delivering maximum accuracy.

We don’t rely on outdated technology like V-rollers or bearing slides. With ShopSabre CNC, you get modern, industry-leading linear motion technology—because that’s what today’s precision demands.

Self-Cleaning Systems, Low Failure Rates

Our triple-sealed linear bearing blocks are built to withstand the harshest environments. When properly maintained, they resist failure even when cutting generates heavy debris and dust. The design naturally deflects contaminants, making our CNC plasma machines virtually self-cleaning during operation—no need to constantly wipe down rails or monitor for buildup. Just hit “start” and let it run.

Don’t be misled by flashy competitor lingo like “precision rollers” or “V-guide slides.” These are often just dressed-up terms for lower-quality bearings. True linear guide rails and blocks are the gold standard in CNC precision—and that’s exactly what we use.

A Better Drive System

ShopSabre plasma tables use a dual-drive rack and pinion system along the Y-axis, but with a twist: we’ve engineered our own Floating Drive System—a proprietary innovation you’ll only find on ShopSabre machines.

This system tackles common rack-and-pinion issues like gear wear, debris buildup, and inconsistent accuracy. By inverting the drive rack, we prevent slag and dust from accumulating. Our independent tensioning system allows each gear to self-adjust without relying on gravity, air cylinders, or external components prone to failure.

This means the system maintains consistent gear tension across the entire rack, even if certain areas see more wear over time. Most machines wear unevenly, leading to skipped steps or stripped gears. Ours adapts automatically—preserving precision and extending machine life. With the floating drive system, you get smoother motion, better cuts, and a long-term competitive edge.

True CNC Router Capabilities—on a Plasma Table

Like all ShopSabre machines, our plasma systems feature industrial-grade ball screw drives on the Z-axis, similar to those used in high-end CNC routers and mills.

Why does that matter? Because we’re also a leading American-made CNC router manufacturer. That expertise allows us to give the ShopSabre SideKick CNC Plasma true routing capabilities—not a bolt-on afterthought.

Other plasma machines may offer router attachments, but they don’t tell you the truth: routing forces require heavier-duty X and Z axes than what most plasma systems are built to handle. At ShopSabre, we integrate routing-grade construction into our design from the start—so you don’t have to compromise on precision or performance.

Simply put, we’re the only machine in this price range backed by over 20 years of full-scale CNC router manufacturing experience.

Powerful Motors

Every ShopSabre CNC plasma is powered by Closed Loop High-Torque Motors with real encoder feedback. Our Y-axis alone delivers more torque and precision than many competitors’ entire machines combined.

Many low-cost machines rely on Chinese stepper motors or underpowered DC servos, which is why they’re paired with lightweight aluminum gantries. That trade-off results in slower acceleration, poor cut quality, and greater heat distortion in your materials.

Our systems use matched, name-brand motor technology—built for speed, precision, and longevity. Higher acceleration and deceleration rates allow cleaner corners and sharper circles, reducing heat buildup and minimizing warping.

Don’t be fooled by buzzwords—“servo” and “stepper” mean nothing without quality engineering behind them. ShopSabre motors are chosen for one reason: they’re the best match for our machines’ industrial design.

With ShopSabre, you get the kind of motor performance, precision engineering, and structural integrity normally found in machines two or three times the price. We build CNC systems that outperform expectations—without breaking the bank.

ShopSabre CNC Controller

ShopSabre CNC Controller

Power of Industrial Technology, Convenience of a PC

At ShopSabre, we combine industrial-grade technology with the convenience of a PC-based interface. Unlike many competitors, we don’t use cheap hobby controllers like Mach 3 or proprietary systems that can cause programming headaches. Instead, we install an industrial PCI controller into a PC tower, giving you both power and ease of use.

This setup makes the ShopSabre control system one of the most user-friendly industrial controllers on the market, while maintaining the precision and performance you’d expect from a high-end CNC system. We also don’t rely on flimsy printer ports or USB cables for machine communication. Instead, our systems use a high-definition 37-pin CNC-grade connection to ensure clean, uninterrupted communication between the PC and the machine.

Why does that matter? Because USB was designed for one-way communication—like syncing a phone or camera. CNC machines require constant two-way communication, and breakdowns in that communication can result in jagged edges, poor cuts, or random unprogrammed movements. ShopSabre avoids that entirely.

And because we don’t limit you with a closed-off controller or what some call “tunnel vision,” you can edit drawings, store files, or even install CAD software directly on your machine’s PC. With 250GB of solid-state storage and a Windows-based OS (not used to run the machine but available for convenience), you get the best of both worlds—performance and flexibility right at the machine.

No Special Training, Maximum Capabilities

The ShopSabre CNC control system is intuitive and easy to learn—no special training required. It offers the same user-friendly experience found on entry-level systems, but with the capabilities of $100,000+ machines.

The system features a dedicated PCI card that drives only the CNC machine, while the PC processor handles your CAD software or background tasks. You’ll also have access to USB ports, external storage compatibility, Ethernet and network capabilities—everything you need for a seamless workflow.

Despite what some commission-driven sales reps claim, not all PC-based controllers are “hobby-grade.” The ShopSabre CNC system offers every capability of standalone controllers and adds features many competitors can’t, including:

-

Auto Machine Squaring

Automatically aligns and squares itself daily, ensuring true cuts every time. -

Kerf Compensation

Adjusts for flame kerf so your holes stay round and your cuts stay straight. -

Template Tracing

Easily trace templates or broken parts—perfect for creating mock-ups or fabricating replacements on the spot. -

Direct Import

Load a .DXF file and start cutting in seconds. -

Sheet Alignment

Align heavy or mispositioned plates using torch or laser corner references. The machine auto-skews the drawing to match the sheet for optimal nesting and minimal waste. -

Restart Feature

Stop and restart your file at any point on the table with the press of a button—no need to scrap material if a tip-up or torch-out occurs. -

Integrated Cutter Settings

When paired with a Hypertherm system, pre-loaded Powermax settings allow you to select material and automatically apply the correct speed, height, torch settings, and consumables—no manual input required.

This is just the beginning. Additional capabilities like photo recognition, image scaling, and art import via ShopSabre QuickDraw & EnRoute Fabrication give you even more creative control. The only real limit is your imagination.

And yes—our PC controller is built for the shop environment. Dust and dirt won’t slow it down. Worried about Windows updates? Don’t be. Our engineers have spent years perfecting compatibility, and ShopSabre offers lifetime updates to keep your system running smoothly—no hiccups, no outdated software, and no surprises.

Digital Torch Height Control

Digital Torch Height Control

Control Your Torch Height

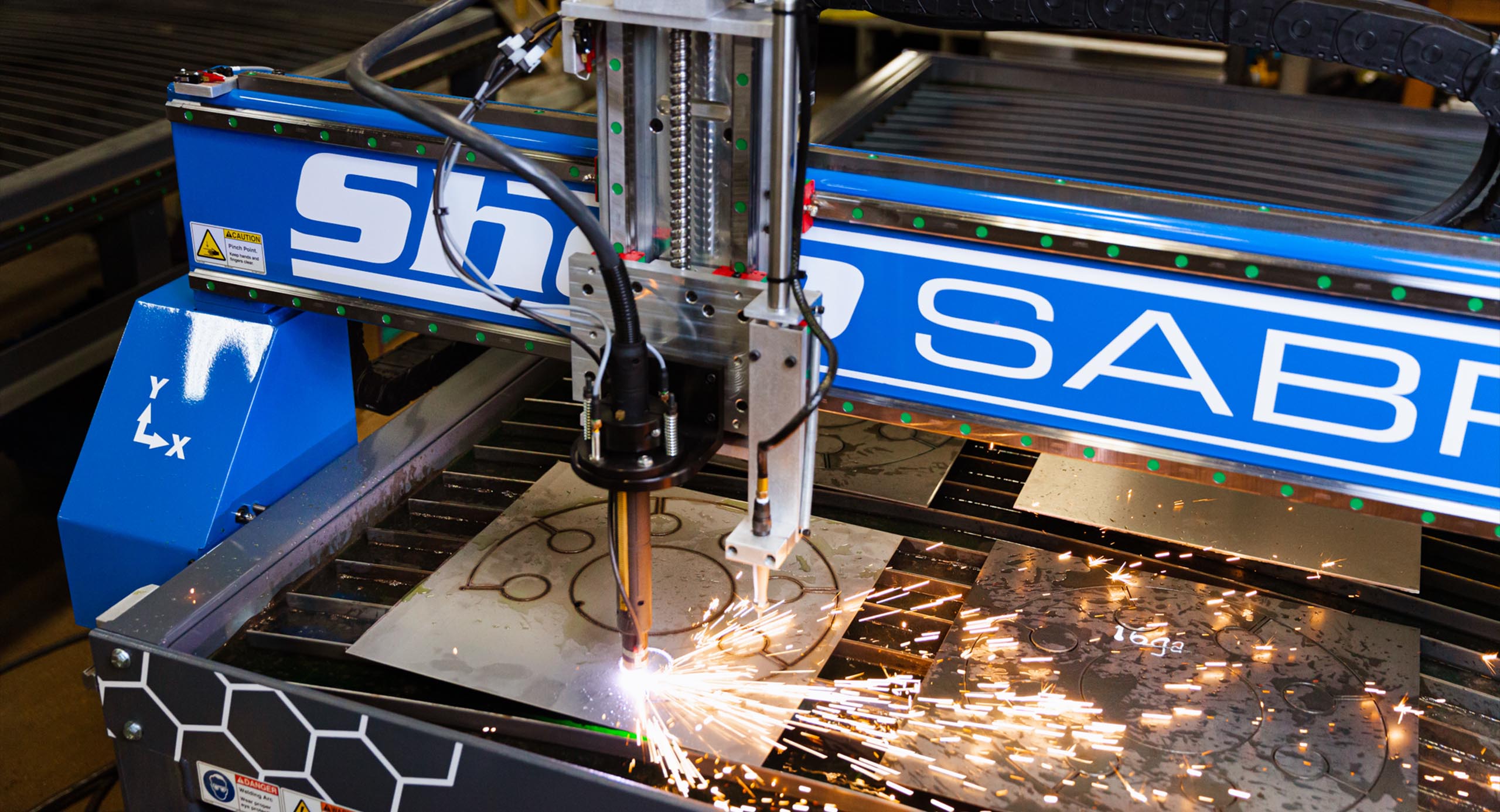

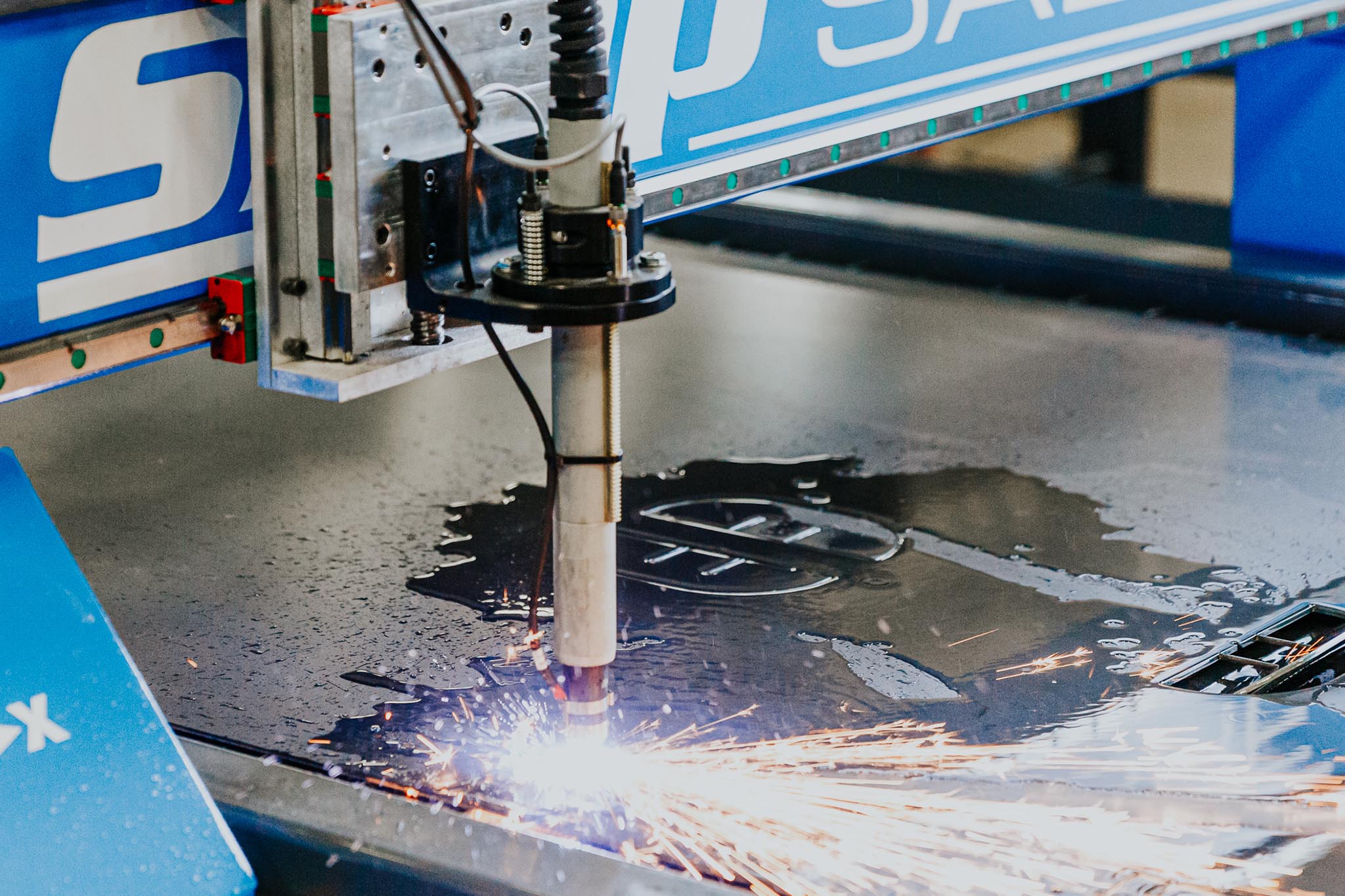

Every ShopSabre CNC plasma machine comes standard with integrated digital torch height control—not as an afterthought, but as a seamlessly embedded feature that enhances every cut.

Contrary to popular belief, torch height control isn’t used on all materials. It’s most effective when cutting warped or thinner materials—typically ½” and below—where maintaining consistent torch distance is critical. Unlike many competitors who rely on standalone boxes or third-party add-ons, ShopSabre’s torch height control is fully integrated into the machine and accessible directly from the operating screen. That means faster response times, higher precision, and on-the-fly control with just a button press.

More Accurate Cuts

While other brands wire external boxes to their cutter and computer, ShopSabre connects directly to the OEM ports designed by Hypertherm and Thermal Dynamics—no messy workarounds, no signal loss, no guesswork.

Our system continuously reads and monitors real-time voltage, adjusting the torch height throughout the entire cut. Many systems only measure voltage briefly at the beginning, then cut “blind.” ShopSabre’s real-time monitoring compensates for variables like rust, uneven surfaces, or warping—keeping the torch in the flame’s optimal sweet spot for a cleaner, straighter cut with minimal beveling.

The result? More accurate parts, longer consumable life, and better overall performance.

You can even set custom torch height delays, making it easy to cut corrugated or extruded metals with precision and reliability. With over 15 years of field-tested success, our torch height control system is in a class of its own—outperforming anything else at this price point.

Hypertherm and Thermal Dynamics Torch Compatibility

Hypertherm and Thermal Dynamics Torch Compatibility

Trusted Torch Compatibility

ShopSabre CNC plasma cutters are fully compatible with two of the most trusted names in the industry: Hypertherm and Thermal Dynamics. Our strong partnerships with both companies allow us to work closely with their technicians and sales teams to deliver the highest-quality cutters available today. If you’re not using one of these leading torch brands, you’re likely sacrificing cut quality.

Certified Technicians, Certified Quality

Our technicians attend official certification classes from both Hypertherm and Thermal Dynamics, ensuring we stay fully aligned with the technology you’re investing in. ShopSabre is also one of the few CNC manufacturers certified in Hypertherm’s elite XPR class of plasma systems—something most CNC brands can’t claim.

This relationship isn’t just professional—it’s personal. Many Hypertherm and Thermal Dynamics employees use ShopSabre machines in their own shops, a testament to the trust we’ve earned through years of collaboration and proven performance.

Don’t settle for less experience or support when you can have a system that combines certification, credibility, and long-term reliability—without paying more.

More ShopSabre Advantages

-

Fully Tested Before It Ships

Every ShopSabre CNC plasma machine is 100% tested before it leaves our facility—so you’re not the field tester. Your machine arrives ready to get to work. -

Precision Machined Mounts

We precision-machine every tool plate and mounting bracket to exact specifications, minimizing wear, maximizing accuracy, and ensuring smooth operation. -

Premium CNC Wiring

Our systems use high-grade continuous-flex robotics wiring, specifically built for plasma use. This wiring withstands constant motion and includes anti-interference coatings to prevent electronic noise—something many competitors skip, even at similar prices. -

Field-Upgradable Options

Want to start basic and add upgrades later? No problem. Most features can be added after purchase—ask our sales team for details. -

Easy Maintenance Design

ShopSabre systems are designed for ease of use and serviceability. Most customers—even with zero CNC experience—are running within hours of delivery. -

Free Lifetime Tech Support

We believe in backing what we build. That’s why we offer free lifetime tech support via internet, phone, or email—no surprise bills, ever. -

Free Lifetime Training Access

Every customer gets unlimited access to SabreNation University, our training portal that helps you learn, grow, and master your machine at no additional cost. -

No-Commission Sales Team

Our consultants aren’t paid on commission, so they’re here to help—not upsell. You’ll get honest guidance based on your needs, not their paychecks. -

Built Around You

We never cut corners to close a sale. Instead, we focus on building the right system for your workflow and budget—because long-term success is the only sale that really counts. -

Backed by Warranty

Every machine includes a complete warranty, giving you peace of mind and confidence in your investment.

Don’t be fooled by lesser systems. We’re so confident in our CNC plasma machines that we invite you to visit our facility and see the quality firsthand. With pricing starting under $15,000, the right machine is within reach.

Buy your second CNC plasma table the first time—and be proud of your investment. Avoid the regret and wasted time of buying again. Contact our sales team today to request a quote or learn more.

RELATED MACHINES

ShopSabre TC Series

ShopMaster CNC Plasma

Sidekick CNC Plasma