EVERYTHING YOU NEED IN A CNC ROUTER

When buying a CNC router, service and quality are the two most critical factors. You need a machine that works when you need it—and it needs to deliver excellent performance every time you put it to work. At ShopSabre CNC, we’re committed to building CNC routers with unmatched quality and value, backed by unbeatable customer service. Ultimately, the build quality and technology determine your machine’s life expectancy and performance capabilities.

CNC machines are a significant investment, and many people are tempted by low prices claiming to offer the same capabilities. But many of these options are simply Chinese imports, low-quality builds, or DIY kits—all with inferior components and outdated technology, which is how they cut costs. If you buy one of these machines, chances are you’ll soon be shopping for a replacement.

That’s why we say, “Buy your second machine the first time.” Avoid the hassle, headaches, and hidden costs that come with lower build quality or non-American-made equipment.

Don’t be fooled by flashy claims like “fastest-growing” or “more industrial.” The facts are clear: more people trust the ShopSabre CNC brand than any other manufacturer, thanks to our quality and competitive pricing. That trust has made us a true industry leader in the CNC router market. With more and more customers replacing competitor machines with ShopSabre every month, the advantages speak for themselves—and our customer retention proves it.

Below, we’ve outlined the key elements of a CNC router to help you understand why ShopSabre is the best CNC router manufacturer for your money—and how our machines give you a true edge over the competition. We also encourage you to compare our systems with higher-priced routers. With similar components, materials, and design, you’ll quickly see why ShopSabre delivers the best performance at the best value.

FRAMEWORK

Structural Strength

ShopSabre CNC routers are constructed from top-rated North American structural steel tubing and heavy-wall steel plate. We don’t use fabricated tubing (bent steel), extruded aluminum, or angle iron in our machine frames. Each system is fully welded—no assembly required—giving you the same structural quality found in machines that retail for over $100,000.

Unbeatable Precision and Accuracy

Our frames are engineered to handle the toughest projects with precision and reliability. The base of every machine is stress-relieved to reduce tension, and our PRO, IS, and IS-M Series frames are aerospace-milled to achieve tight tolerances and superior accuracy. Each frame then goes through a series of quality tests, including Faro arm measurement, to ensure it meets both our standards and yours.

But we don’t stop there—we also stress-relieve and mill the gantry to guarantee squareness between the frame and gantry. These steps ensure you get the most rigid and accurate assembly in the machine class.

In the PRO, IS, and IS-M Series, aerospace milling of the frame, gantry, and related components is standard. These machine tool-grade solutions eliminate tolerance issues before they become your problem.

Ultimately, a CNC machine is only as good as its foundation. Don’t settle for a router that’s bolted together, pulled from a shelf, or imported from overseas to be resold. Our frames are engineered works of art, created with high-end FEA (Finite Element Analysis) software to optimize load performance. And with over 20 years of experience, we’ve proven our machines can handle the growth and evolution of your everyday business.

Gantry Construction

Gantry Construction

Industrial Quality

No matter which ShopSabre CNC router you choose, we never slap a lightweight gantry onto an industrial frame and call it done. Every ShopSabre CNC router comes standard with a structural tube steel gantry that’s been precision-milled and stress-relieved for long-term durability and performance.

We design every gantry using the same advanced FEA (Finite Element Analysis) software used to engineer our machine frames—ensuring the bearing spacing, tube sizing, and wall thickness are perfectly matched to the demands of each machine.

In fact, our PRO, IS, and IS-M Series routers use the same gantry construction found in high-production, $100,000+ machines. Even our most economical model, the ShopSabre 23, features a steel gantry spanning bridge to enhance rigidity and cutting precision.

ShopSabre goes above and beyond by pairing industrial frames with true structural steel gantry bridges—because details matter. And it’s our attention to those details that ensures your router performs with unmatched precision.

Industrial Performance

ShopSabre routers also feature paired oversized structural steel gantry uprights—standard on the IS-M, IS, PRO, and RC Series. This design allows you to push your machine harder and faster under load, with less deflection, reduced harmonics, and fewer cut-quality issues.

Thanks to this reinforced design, we’re also able to offer higher machine clearances than most competitors—giving you a real advantage when working with thicker materials or taller fixtures.

Many machines claim to be industrial, but if you take a closer look at their gantries, you’ll find few can truly compare to the engineering and build quality of a ShopSabre CNC router.

Aluminum-frame CNC machines? A thing of the past. They only benefit the manufacturer, not the user. Aluminum allows for cheaper electronics and increased margins, but comes at the cost of rigidity, precision, and long-term performance.

There’s a reason high-end routers and milling centers don’t rely on aluminum. It all comes down to proper engineering—and that’s why we use high-strength structural designs to maximize cutting speed, improve performance, and keep your machine rock-solid for years to come.

Motion Components (Drives, Guides, and Motors)

Motion Components (Drives, Guides, and Motors)

High-Precision Components

All ShopSabre CNC routers are built using the same high-precision components across every model. We use top-rated 25mm linear guide rails paired with matching 25mm linear guide bearing blocks—featuring internal quad roller sets and triple wipers—on every axis of every machine. Each axis uses two bearing blocks per rail and two rails per axis to evenly distribute cutting forces. This results in reduced wear, quieter operation, and greater long-term reliability.

Many competitors cut corners by using off-brand bearings, undersized 15–20mm rails, outdated precision roller or V-guide systems, or lower-performance “precision slides.” These lighter-duty alternatives can’t compare to the durability and accuracy of a ShopSabre CNC router.

Another major advantage? Our wider bearing spacing—engineered using advanced FEA software—gives you greater cutting stability and support under load.

Just like a football player widens their stance for leverage, ShopSabre’s bearing layout gives you a real-world advantage in both performance and control.

Self-Cleaning Systems, Low Failure Rates

Our triple-sealed bearing blocks are built to perform in harsh shop environments. No matter how much dust or debris your project kicks up, you won’t experience bearing failure when the system is properly maintained.

This design makes the router effectively self-cleaning during operation—no constant rail wiping or babysitting required. Simply start the job and come back when it’s done.

On our PRO, IS, and IS-M Series routers, we go even further by shielding the Y-axis rails, limiting exposure to dust and debris and significantly reducing your maintenance time and costs.

Best-in-Class Ball Screws

Our Machine Tool Grade routers—the ShopSabre PRO, IS, and IS-M Series—feature high-precision ball screws on all three axes (X, Y, and Z). These are built with our exclusive “Whip-Free” design and matched ball nuts, using some of the largest diameter screws in their class—comparable to what you’d find in routers costing over $100,000.

We don’t cut costs with smaller, flimsy ball screws or cheap lead screw technology. ShopSabre systems use industrial-grade components that rival far more expensive machines, both in performance and durability.

Key features include:

-

Dual Y-axis drive systems on PRO, IS, and IS-M models for even cut force and enhanced precision across the entire table.

-

Anti-backlash ball nuts mounted in angular contact bearing blocks to maximize accuracy.

-

Rotational ball nut technology to completely eliminate whip—a common problem in older or less refined designs.

Compare that to competitors using lead screws or rack-and-pinion systems. These outdated methods can cause unnecessary wear on X and Y axis components and reduce your machine’s precision and cut quality over time. With ShopSabre, you’re investing in the latest technology—not yesterday’s shortcuts.

Advanced Servo Motor Systems

All RC, PRO, IS, and IS-M Series routers come standard with Servo Control Systems. Our PRO, IS, and IS-M models are equipped with the industry-leading Mitsubishi A/C digital super servo drives, complete with matching amplifiers and glass encoders for unbeatable accuracy.

These motors offer:

-

The highest torque

-

The most dependable operation

-

The highest resolution and accuracy in the class

In fact, the IS and IS-M Series routers are the only machines under $70,000 in the U.S. to offer:

-

Dual Y-axis ball screw drives

-

2 kilowatts of Y-axis power

-

Fully American-made construction

You’re getting the quality of a six-figure industrial router at a fraction of the price.

A higher price tag doesn’t always mean better technology. Let the facts speak for themselves: nobody offers more advanced drive system tech in this class than ShopSabre.

At ShopSabre, you always get the best technology for the lowest investment.

Ask our sales team for more information about our drive systems. We promise—you won’t be disappointed.

ShopSabre CNC Controller

ShopSabre CNC Controller

Power of Industrial, Convenience of PC

At ShopSabre, we give you the best of both worlds when it comes to CNC control. Unlike many competitors, we do not use cheap hobby controllers like Mach 3—and we definitely don’t lock you into a proprietary system that causes compatibility headaches down the line. Many of those lower-end solutions lack the technology to stay current, leading to programming issues and limited upgrade paths.

Instead, we use an industrial PCI-driven controller, seamlessly integrated into a PC environment. This setup gives you maximum control and flexibility while keeping the system user-friendly.

From the outside, it may look like a standard PC—but inside, it’s packed with industrial-grade CNC control hardware, including a dedicated microprocessor and components found in standalone control towers that cost thousands more. And just like our machines, our controller is made in the USA for superior support and long-term reliability.

Our CNC routers are built to offer the motion control precision you expect from a professional system—without the intimidating complexity of a traditional control tower.

CNC controllers have never been this easy to operate. Many ShopSabre customers—even those with zero CNC experience—are running their machines in as little as 2 hours after setup.

Don’t settle for systems that require days of training. Our controller is fast, intuitive, and powerful.

Ask us for more details.

Top-Quality Connection

We don’t rely on USB, serial, or printer ports to connect your machine. ShopSabre CNC routers use a true CNC-grade 37-pin high-definition connection, built for real-time, two-way communication.

And because it’s a full PC system, you can:

-

Store files locally with a 250GB solid-state hard drive

-

Run CAD software directly on the machine

-

Perform onboard diagnostics

-

Network your machine

-

Operate Windows-compatible programs—without interfering with machine control

No walking back and forth between computers—everything you need is right at the machine.

No Special Training, Maximum Capabilities

The ShopSabre CNC controller requires no special training. It’s designed to be as simple and intuitive as hobby-grade systems, but with the power and capability of machines costing over $100,000.

Here’s how it works:

-

A dedicated microprocessor handles all motion control

-

The PC processor runs your software and Windows-based programs

-

The Windows OS is present—but does not control the machine, ensuring full stability

-

USB ports, Ethernet, network access, and optional wireless connections come standard

Not Your Average PC-Style Controller

Some competitors may try to convince you that all PC-based controllers are hobby-grade. That’s just not true.

Technology has evolved. If you can control your garage door, lights, and security system with a smartphone, why wouldn’t your CNC router benefit from the same level of modern control?

With over 20 years of innovation, our CNC controller is highly compatible, user-friendly, and packed with features typically reserved for six-figure machines.

ShopSabre systems include advanced functions such as:

-

Job and part preview

-

On-machine CAD editing

-

Onboard diagnostics

-

Bit offsets and compensation

-

Tracing and direct import

-

Jig setup memory

-

Job restarts and re-runs

-

Speed/feed override

-

Mid-file tooling changes

-

And much more

Our controller is designed to perform in industrial environments—so dust and debris won’t cause issues.

And don’t worry about Windows updates. While competitors may treat them like a system failure, ShopSabre machines are built to evolve with technology. Our engineers have created a system where everything works in harmony. You can update Windows and stay current without breaking your machine’s control system.

Lifetime updates and FREE lifetime support ensure your ShopSabre CNC grows with your business—not against it.

Want a Dedicated Controller? We’ve Got That Too.

For those who prefer a standalone controller, ShopSabre is proud to be the first CNC router manufacturer in the world to pair routing technology with the Mitsubishi M8 Series Controller, available on our IS-M Model.

The M8 Series is the world’s fastest CNC control—now combined with the ease of the ShopSabre interface. It offers exceptional speed, precision, and reliability, making it the most accurate and capable controller in the industry.

And yes—it’s standard on the IS-M Series.

Hold Down (Vacuum & Clamping)

Hold Down (Vacuum & Clamping)

Built for Your Needs and Your Budget

ShopSabre CNC routers offer solutions for every budget and production level—whether you’re a high-volume cabinet shop, a custom sign maker, or a prototyping lab working on the next big thing. We provide a range of vacuum hold-down options tailored to your needs, including:

-

The industry’s most powerful single-phase vacuum system

-

High-performance three-phase solutions

-

Optional T-slot tables for clamp-based setups

-

And our hybrid vacuum/T-slot combo tables for ultimate flexibility

Whether you’re just getting started or already deep in production, we’ll help configure the right hold-down system for your workflow—without forcing you into features you don’t need or can’t afford.

A League of Our Own

What sets ShopSabre vacuum systems apart? Simple: they’re purpose-built for each machine size. With our HiFlow vacuum option, you get more CFM, better suction, and more reliable hold-down performance—because the system is specifically engineered for your table.

Other companies often cut corners with:

-

One-size-fits-all “universal” vacuum tables

-

Undersized pumps with insufficient CFM

-

Cheap flexible tubing that reduces efficiency

These setups struggle—especially on 4×8, 5×10, and larger systems—leaving you to deal with the frustration of materials shifting during a cut.

In contrast, ShopSabre pairs each router with industrial-grade, high-suction pumps, often delivering nearly twice the suction power of comparable systems—for a similar price. Our vacuum tables also include independent vacuum zones, so you can shut off suction to unused areas and focus it where you’re actively cutting. No wasted power. No wasted time.

ShopSabre’s HiFlow Vacuum technology delivers up to 50% more flow than competing machines. And as we like to say:

“You can’t cut what you can’t hold down.”

We’re also one of the few companies that has truly engineered the vacuum table top for optimal performance, ensuring even airflow across the surface. Most users won’t even need gasketing—but if you prefer it, our design supports that too.

More Versatile Machines

Our hybrid T-slot clamping tables were introduced to give users enhanced flexibility without the high cost of a full aluminum table top. We recess aluminum T-tracks into the table surface and bolt them to the steel frame below, giving you rock-solid clamping options at a fraction of the price.

All T-slot table setups come with a set of industrial-grade clamps, so you’re ready to work right out of the gate.

Don’t settle for machines that force you to slow your cuts down or rely on tape, glue, or screws to hold material in place. A ShopSabre vacuum or T-slot system makes setup faster, easier, and more professional—so you can stay focused on production, not problem-solving.

The Birth of ShopSabre CNC

The Birth of ShopSabre CNC

While constructing his next CNC router, Jim performed more market research and was amazed that no one offered an industrial quality machine under $60,000. Jim decided to take his design to the Woodworkers show in Atlanta, GA, where he received a lot of attention, accolades, and over a dozen requests for orders. Potential customers were willing to wait for their new machines as they understood the quality and components put into the design.

After returning home, Jim constructed a facility for the manufacturing of CNC machines in the U.S.A. With the help of his two brothers, four sons, two cousins, and his wife, Jim opened ShopSabre CNC and began changing the way the CNC industry works.

A few years after opening, Jim developed the first ShopSabre CNC plasma machine along with the technology that would make ShopSabre a leader in its class.

Spindles/Cutter Heads

Spindles/Cutter Heads

The Right Options for Your Needs

ShopSabre CNC router systems offer spindle solutions to match any budget and application. For smaller shops, our ShopSabre 23 and RC models come standard with a 3.25HP Porter Cable variable-speed router, complete with an industrial power cord and machine mounting bracket.

For more industrial needs, our PRO, IS, and IS-M Series machines come standard with Italian-made, electric fan-cooled HSD spindles, available in manual, quick-change, or automatic tool-changing configurations.

Popular spindle options include:

-

4HP HSD electric fan-cooled spindle with ER25 collets

-

9.3HP HSD electric fan-cooled spindle with ER32 collet system

-

5HP and 10HP HSD auto tool changer spindles, compatible with ISO30 and ER32 (HSK options also available)

-

13HP HSD HSK spindle, standard on the IS-M Series

Need something unique? Special-order spindle options are available for more specialized applications.

Everything You Need

Every ShopSabre spindle includes a high-quality Variable Frequency Drive (VFD), offering full RPM control (1,000–24,000 RPM, model dependent). Our VFDs run on single- or three-phase power at no extra cost, so you can install your ShopSabre in a home garage or full-scale production shop without compromising performance.

Because we use high-quality, S1-rated VFDs, you get:

-

100% duty cycle operation

-

Higher load capacity

-

Longer spindle life

-

No power loss, even on single-phase setups

We also offer multiple tool changer options, including:

-

5-position or 10-position tool racks

-

10-position rotary direct-drive carousel tool changer with bi-directional rotation on the IS-M Series

And unlike many competitors, we don’t sell you a tool changer with just one usable position. When you purchase a 5-position tool changer, you get:

-

5 full positions

-

Collets

-

Tool cones

-

Tool forks

-

Wrenches and vise—everything you need to get to work, day one

Every ShopSabre router also includes a tool measure switch by default, regardless of tool changer size. This means you’ll never lose a tool position just to measure—it’s all integrated with performance in mind.

Top-Rated Spindles

Still unsure? We encourage you to research HSD spindles and compare them to others on the market. HSD is consistently rated among the best spindle manufacturers in the world.

Our HSD spindles are:

-

Italian-made (widely recognized for the best spindle craftsmanship)

-

Supported in the U.S.A.

-

Built for years of reliable use with little to no maintenance

Many lower-priced machines cut corners by using off-brand, air- or water-cooled spindles from overseas, often sold at near the same price point as our superior components. These alternatives typically:

-

Require more maintenance

-

Need additional equipment (especially water-cooled models)

-

Suffer from inconsistent cooling and reduced duty cycles

-

Offer weaker torque and shorter lifespan

Water-cooled spindles, in particular, are less efficient—they only cool while running and often rely on clunky add-ons like buckets and pumps. In contrast, ShopSabre’s electric fan-cooled spindles provide:

-

Superior torque curves

-

Consistent cooling (fans run anytime the spindle is hot)

-

Longer duty cycles

-

Lower maintenance and energy use

No water buckets. No gimmicks. Just clean, reliable power and performance.

Ready to take the next step?

Contact our sales team to learn how a ShopSabre CNC router—equipped with the right spindle and tool changer—can make a difference in your shop.

RELATED MACHINES

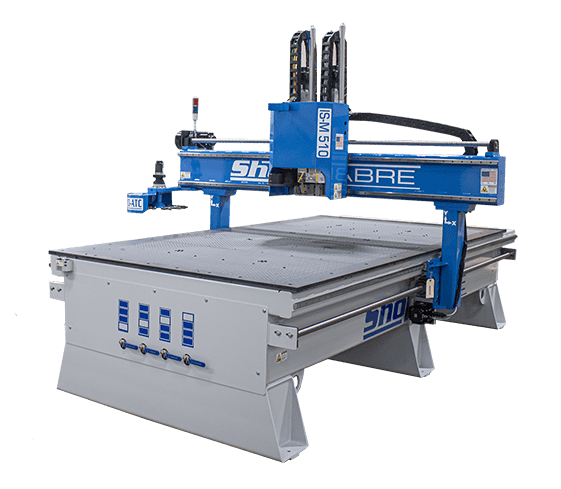

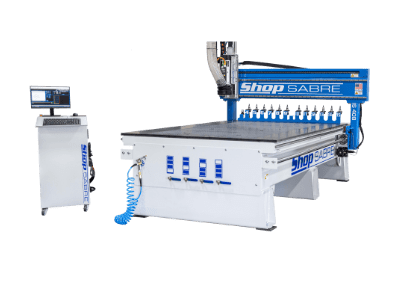

Industrial Strength Automation Series

IS-M Series

Industrial Series (IS)

IS EVA Series

PRO Series

RC Series