Helping Engberg Construction ramp up production and quality

For small businesses, CNC technology can play a significant role in ramping up production and accelerating timelines on the way to higher profits.

Engberg Construction in Red Wing, MN, experienced this impact firsthand as the addition of a CNC router allowed it to scale its cabinetmaking offering while also providing increased precision and quality.

Here’s how Engberg Construction used the power of CNC to go from outsourcing its cabinetmaking to producing one-of-a-kind, professional-grade cabinetry in a fraction of the time.

Bringing cabinetmaking in-house

Mike Engberg founded Engberg Construction in 2009 as a two-man operation that specialized in home remodeling. At the time, what little cabinetry was required was outsourced a process that typically came with a 4-5 month timeline and that prevented proactive planning on most projects.

In 2015, Mike purchased a ServiceMaster Restore franchise for commercial and residential restorations. This acquisition led to an increased need for new cabinetry on tighter timelines, as homeowners wanted their kitchens done in a few weeks not several months.

Mike realized the only solution that would provide them with full control over quality and production turnaround would be to bring cabinetmaking in-house. And doing so would require an equipment upgrade.

Making the switch to CNC

In bringing cabinetmaking in-house, Mike began looking at equipment and processes that would allow them to be more productive and efficient without having to hire several new employees.

Mike started looking into CNC machines online and was initially discouraged by the price tag of more than $100,000 from many manufacturers, as this size of an investment was simply not feasible for a small, two-man operation.

After a couple more months of research, Mike stumbled upon ShopSabre and decided to give the shop a call. After speaking with the team, he drove to the shop to look at some machines in person.

Mike is not a machinist by trade, which made CNC a whole new avenue for him. While at the shop, he spoke directly with CNC experts who helped educate him on the industry and the right machinery for his application.

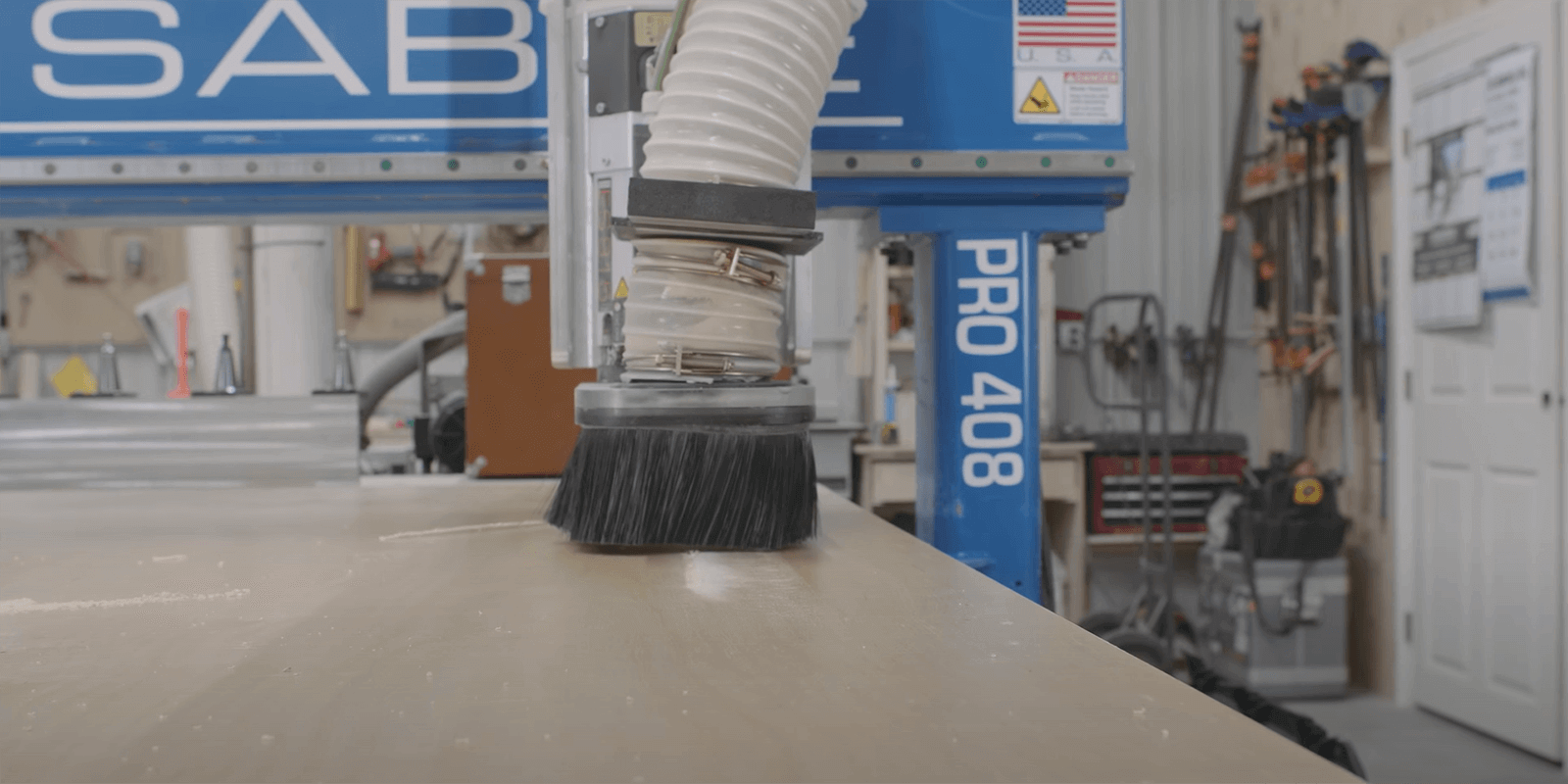

After a bit more research, Mike eventually pulled the trigger on a ShopSabre PRO Series 408 CNC router.

CNC changes the game

In setting up the shops new CNC router, Mike brought in two more experienced employees to help run the shop, neither of whom had much experience in the CNC world. This may have been intimidating at first, but the learning curve proved easy, resulting in quick turnaround getting everything up and running.

Now, two employees were able to stay on top of orders and get them punched through quickly, turning the months-long lead times of other cabinetmakers into 2-3 weeks with the help of CNC.

The CNC is definitely the way to go, there’s no doubt about it, Mike said. That machine will pay for itself in no time. It is probably the most valuable employee you have.

Optimizing workflow

Now that the CNC router was up and running, Mike wanted to make sure the workflow was optimized for efficiency and accuracy. A key desire was the ability to draw the kitchen and cabinet designs on a software program that was easy to view, manipulate, and change to show customers early on in the project process. Mike also wanted to optimize yields and sheets to ensure the shop wasn’t wasting an excess of material.

As far as execution, Mike wanted a platform that would set up all the cuts and drilling while eliminating a lot of the labor involved in doing so manually. Eventually, he came across Mozaik, which had a surprisingly quick learning curve for someone fairly inexperienced in design-to-manufacture software.

In addition to helping minimize material waste, Mozaik also provided precise cutting and repeatability across every part and cabinet.

The guys could literally put the cabinets together, and they couldn’t screw it up, Mike said. You had a perfect cabinet every time. You can’t get that accurate on a table saw. You just can’t.

Looking back on the process

When Mike looks back on the decision to add CNC technology to the shop, he acknowledges he should have pulled the trigger sooner. There was some apprehension early on in the process, but it turned out well, with support from the ShopSabre team along the way.

There wasn’t one issue I had that we couldn’t resolve on the phone in 15 minutes, Mike said. If you’re hesitant about getting into the CNC world, don’t be. The ShopSabre has been great. The support is great. Everything about it has been a good experience.

Take your production to the next level with help from ShopSabre

ShopSabre manufactures world-leading CNC routers and CNC plasmas to provide hobbyists and shop owners alike with unmatched precision, efficiency, and versatility. Whatever your goals may be, we are dedicated to helping you produce outstanding results at a fraction of the labor and cost.

Our Industrial Series (IS) and PRO Series CNC routers provide industrial capability for a fraction of the price, while ourSideKick CNC plasmas deliver professional quality at an entry-level cost.

Here are a few of the reasons ShopSabre is able to develop and produce such revolutionary CNC technology:

- Experienced in-house engineering talent

- The ability to totally fabricate and test designs onsite

- The ability to place the designs into production in-house

These are just a few of the advantages of being an American machine tool manufacturer. We offer commercial financing on our CNC equipment to help meet the needs of your budget.

Shop our unmatched collection of CNC routers and CNC plasmas in Minneapolis today to experience CNC the way it was meant to be.