Oneida 10HP 230V Direct Drive Cyclone Dust Collector w/ Air Lock – No Drum

$13,990.00

Description

Realize the Power of American Manufacturing. Our 10HP Direct Drive system is the workhorse of our industrial line of cyclonic dust collection systems – delivering maximum airflow performance within a compact, quiet, and cost-effective package. Built to last a lifetime using industrial, heavy-gauge steel components, our 10HP is ideal for commercial shops with fixed ductwork and multiple tools in use simultaneously.

Read MoreRead Less

Included Features & Components

- Industrial 10HP U.S. Made Motor

- Backward Inclined, Non-Sparking, Cast-Aluminum Impeller

- High-Efficiency 230V / 3-Phase Power

- Magnetic Starter with Overload Protector

- Heavy-Gauge Solid Welded Steel Cyclone Separator with Clean-Out Access Door

- Modular Stacking Spunbond Cartridge Filters

- Real-time Filter Efficiency Pressure Gauge

- Drop-In Acoustic Foam Filter Silencers

- Industrial Angle Iron Frame Stand

- Rotary Air Lock Feeder Valve

- 2 Year Limited Warranty

Continuously High Airflow Performance

Ultra-High Efficiency Steel Cyclone Separator

High Quality & Serviceable Filtration

Automated Bulk Waste Disposal

Downloads

Specifications

| Horsepower | 10HP |

|---|---|

| Motor Type | U.S. TEFC Motor |

| Motor Service Factor | 1.15 |

| Voltage | 208-230V |

| Amperage (Typical) | 26.2-23.8A |

| Phase (Pre-Wired) | 3-Phase |

| Frequency | 60Hz |

| Power Connector | Bare Wiring (three hot wires & ground) - Licensed Electrician Required |

| Impeller Type | Backward inclined, welded carbon steel |

| Impeller Size | 17" Dia. |

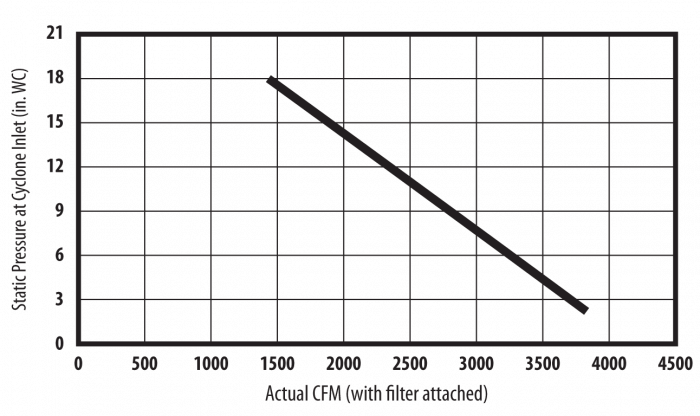

| Real CFM Rating | 3,800 Actual CFM at 2.3" S.P. |

| Noise Level | 84-85 dBA @ 10 ft |

| Filter Type | Izumi Axtar Spunbond Media |

| Filtration Efficiency | 99.9% @ 0.2-2.0 microns |

| MERV Rating | MERV 13 ± |

| 465 sq ft | Customizable |

| Sold Separately | Item #AKR220003 |

| Primary Build Materials | Cold Rolled Steel |

| Welding | Seam Welded |

| Static Resistance Rating | Conductive (Metal) |

| Color | White |

| Inlet Size | Round: 12" I.D. Square ID: 8"(W) x 14"(H) Square OD: 10-1/2"(W) x 16-1/2"(H) |

| Outlet Size | Square ID: 12-1/2"(W) x 10"(H) |

| Discharge Size | 10" I.D. Flange |

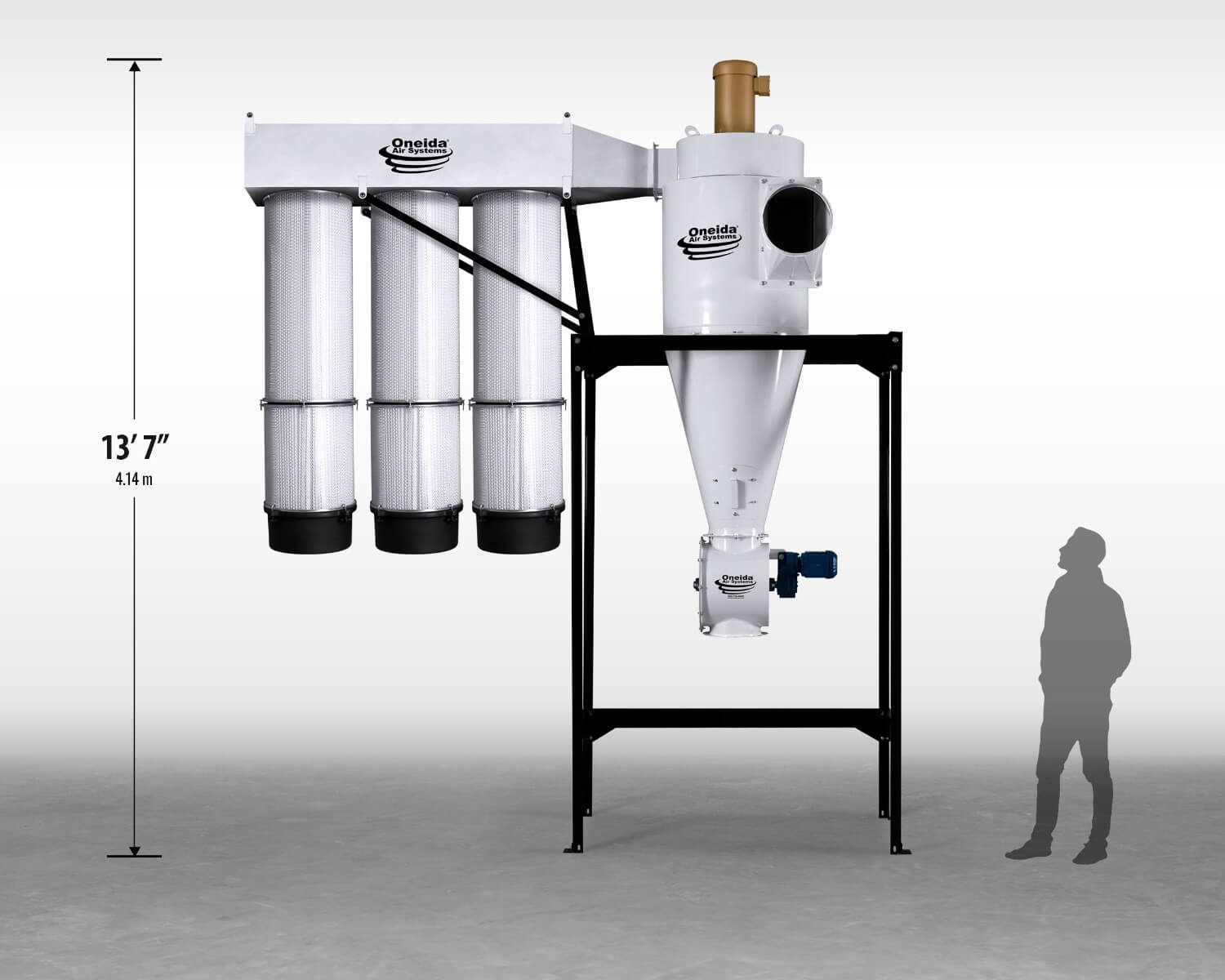

| Width | 122" |

| Depth | 33" |

| Height | 163" |

| Height to Center of Inlet | 131" |

| Contents | Blower Motor Assembly, Magnetic Starter, Fan Housing, Cyclone Separator, Clean-out Access Door, Square-to-Round Inlet Adapter, Filter Plenum, 6x Modular Cartridge Filters, Filter Efficiency Gauge, Angle Iron Stand, Rotary Air Lock Valve, Hardware |

| Country of Manufacture | United States |

| Warranty Information | 2 Year Limited Warranty |

| Certifications | Complete system is cETLus certified for indoor use |

| Applicable Patents | U.S. Patents #7247180, #9370740 |

Finance Calculator

Finance Calculator